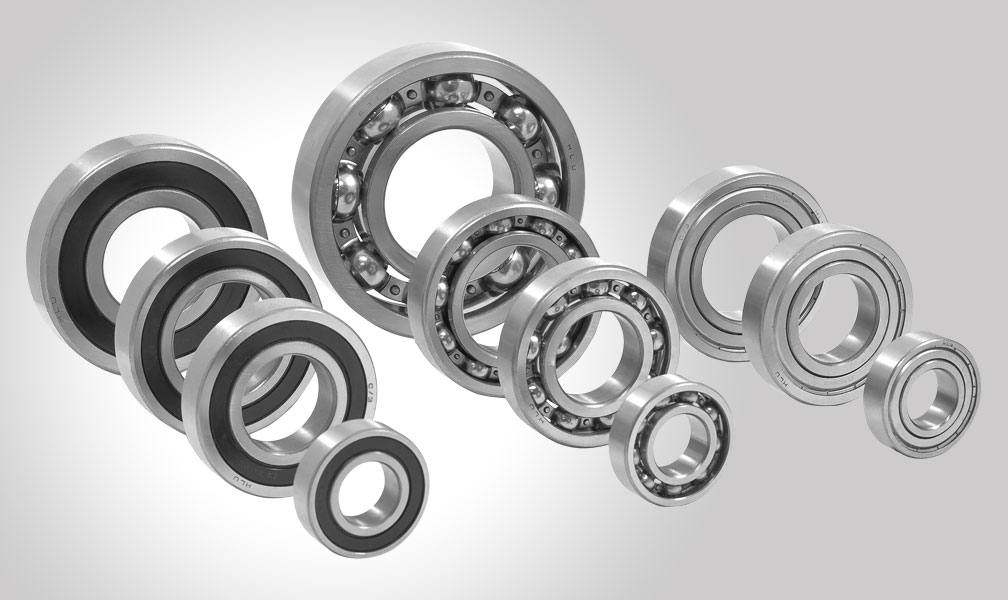

Product Description

The line connecting the steel ball of the angular contact ball bearing with the contact points of the inner and outer rings is at an angle to the radial direction. The contact angle is generally divided into 15°, 30°, and 40°, which are represented by the letters C, A, and B respectively. CZPT specially produces such bearings with a contact angle of 25°, which is represented by A5.

A wide range of applications:

• agriculture and forestry equipment

• automotive and industrial gearboxes

• automotive and truck electric components, such as alternators

• electric motors

• fluid machinery

• material handling

• power tools and household appliances

• textile machinery

• two Wheeler.

Our Bearing Advantage:

1.Free Sample bearing

2.ISO Standard

3.Bearing Small order accepted

4.In Stock bearing

5.OEM bearing service

6.Professional:10 years manufacture bearing

7.Customized bearing, Customer’s bearing drawing or samples accepted

8.Competitive price bearing

9.TT Payment or Western Union or Trade Assurance Order

| Product Name | Angular contact ball bearing |

| Brand Name | HN |

| Seals Type | OPEN/2Z/2RS/Z/RS |

| Material | Chrome Steel ,Stainless steel,Ceramic,Nylon |

| Clearance | C0,C2,C3,C4,C5 |

| Precision Grade | P0,P6,P5,P4,P2(ABEC1, ABEC3, ABEC5, ABEC7, ABEC9) |

| Greese | SRL ,PS2, Alvania R12 ,etc |

| Number of Row | Single Row |

| Certifications | ISO 9001 |

| Package | Box,Carton,Wooden Box,Plastic Tube or Per buyers requirement . |

| MOQ | 10PCS |

| Serice | OEM |

| Sample | Available |

| Payment Term | TT/PayPal/Credit Card |

| Port | HangZhou/HangZhou/ZheJiang |

Angular contact ball bearing modles

707 708 725 725 726

7001 7002 7003 7005 7006 7006 7007 7008 7009 7571 7571 7011 7012 7013 7014 7016 7017 7018

7571 7571 7026 7032 7036 7038 7200 7201 7201 7202 7203 7204 7204 7205 7208 7209 7210 7211 7211 7212 7213 7214

7215 7216 7217 7218 7218 7220 7220 7221 7222 7224 7226 7226 7228 7230 7236 7238 7240 7300 7306 7311 7312 7313

7314 7316 7317 7318 7319 7406 7407 7408 7410 7413 7416 7418 7907 7913 AC B C bearing

3200 3203 3204 3205 3206 3207 3208 3209 3210 3211 3212 3213 3214 3215 3216 3217 3218 3218 3219 3220 3221 3222

3300 3301 3302 3303 3304 3305 3306 3307 3308 3309 3310 3311 3312 3313 3314 3315 3316 3317 3318 3320 4200 4201

4202 4204 4205 5001

Certifications

Packaging & Shipping

ZheJiang Haina Bearing Co., Ltd. is an integrated company of industry and trade. Since its establishment, it has been committed to the research and development, production, and sales of high-end 7 types of tapered roller bearings, British non-standard bearings, deep groove ball bearings, and outer spherical bearings. We can customize and adjust various types of bearings according to customer needs. The products are widely applicablein fields such as automobiles, mines, chemicals, metallurgy, reducers, engineering machinery, agricultural machinery, and electric motors.

Our company has advanced testing equipment, forming a production model of product serialization and mass production. We have a group of experienced and skilled management personnel, who have introduced advanced production equipment and measuringand testing equipment. From the purchase of bearing raw materials to the delivery of finished products, we strictly control the entire process, ensuring the quality of the products.The products have the characteristics of precision, low noise, high load-bearing capacity and long service life.

Q: Are you trading company or manufacturer ?

A: We are manufacturer.

Q:Do you provide samples ? is it free or extra ?

A:Yes, we could offer the sample but it is not free.

Q:What kind of shipment will you use?

A:Boat and FedEx,TNT,DHL,UPS,EMS etc.

Q:could you make bearings with our OEM logo,color and packing?

A: Of course. What you need to do is email us the brand logo and colors.

Q: How long is your delivery time?

A: Generally it is 3-7 days if the goods are in stock. or it’s 15-30 days if the goods are not in stock, it is according to quantity.

Q: Will you check these products before shipment?

A: Yes, before shipment products will be strictly inspection on our factory QC Process System.We have a professional QC team.

Q: What’s the Payment Terms ?

A: Usually we accept T/T ,western union ,and order online.

If you want to know more details, please feel free to contact us. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 25° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Multiple |

| Load Direction: | Radial Bearing |

| Material: | Alloy |

| Samples: |

US$ 1.77/Piece

1 Piece(Min.Order) | |

|---|

Can you describe the load-carrying capacity and load ratings of radial bearings?

The load-carrying capacity and load ratings of radial bearings are crucial factors to consider when selecting and designing bearing systems for industrial applications. Here is a detailed description of these aspects:

Load-Carrying Capacity:

The load-carrying capacity of a radial bearing refers to its ability to support and distribute loads without excessive deformation or failure. It is a measure of the maximum load that a bearing can handle under specific operating conditions. The load-carrying capacity is influenced by several factors, including the bearing size, design, material, lubrication, operating speed, and temperature.

Radial bearings are designed to primarily support radial loads, which are forces acting perpendicular to the shaft’s axis. These loads can include the weight of rotating components, belt tension, pulley forces, or other radial forces. The load-carrying capacity of a radial bearing is specified for radial loads and is typically provided by the manufacturer in terms of dynamic load rating and static load rating.

Dynamic Load Rating:

The dynamic load rating of a radial bearing indicates the maximum radial load that the bearing can withstand under ideal operating conditions, with a calculated 90% reliability over a specified number of revolutions or operating hours. It represents the load at which the bearing is expected to have a basic rating life of one million revolutions.

The dynamic load rating takes into account factors such as the bearing’s geometry, material properties, and internal design, which affect its ability to distribute the load and resist fatigue failure. It is expressed in units of force (often in Newtons or pounds) and is provided by the bearing manufacturer. When selecting a radial bearing, it is crucial to ensure that the anticipated radial load falls within the dynamic load rating to prevent premature bearing failure.

Static Load Rating:

The static load rating of a radial bearing refers to the maximum radial load that the bearing can withstand without permanent deformation or damage while stationary. Unlike the dynamic load rating, the static load rating does not account for the bearing’s ability to handle fatigue-related failures over a specified number of revolutions but focuses on the load capacity under static conditions.

The static load rating is typically higher than the dynamic load rating due to the absence of rotational forces and associated fatigue effects. It provides an indication of the bearing’s ability to support heavy loads without undergoing permanent deformation. Like the dynamic load rating, the static load rating is expressed in units of force and is provided by the bearing manufacturer. It is crucial to ensure that the static load rating exceeds the anticipated radial load to prevent bearing damage or failure.

Load Rating Calculation:

The load ratings of radial bearings are determined through standardized calculation methods based on industry standards, such as ISO and ANSI/ABMA standards. These calculations consider factors such as the bearing’s geometry, material properties, internal design, and expected operating conditions.

The load ratings are influenced by various factors, including the number and size of the rolling elements, the contact angle, the material strength, and the bearing’s internal clearance. Manufacturers perform extensive testing and analysis to determine the load ratings of their radial bearings and provide the values in their product catalogs to assist engineers and designers in selecting the appropriate bearing for specific applications.

In summary, the load-carrying capacity and load ratings of radial bearings play a critical role in determining their suitability for various industrial applications. The dynamic load rating indicates the maximum radial load that a bearing can handle under ideal operating conditions and a specified reliability level, while the static load rating represents the maximum radial load the bearing can withstand without permanent deformation while stationary. Understanding these load ratings is essential for selecting radial bearings that can reliably and safely support the anticipated loads in industrial machinery and equipment.

Are there specific types of radial bearings, and what are their unique characteristics?

Yes, there are several specific types of radial bearings, each with its unique characteristics and applications. These types of bearings are designed to accommodate different loads, operating conditions, and specific requirements. Here are some commonly used types of radial bearings along with their unique characteristics:

1. Deep Groove Ball Bearings:

Deep groove ball bearings are the most common type of radial bearings. They have deep raceway grooves that enable them to carry both radial and axial loads. Deep groove ball bearings are known for their versatility, high-speed capability, and relatively low cost. They are suitable for a wide range of applications, including electric motors, appliances, automotive components, and machinery.

2. Angular Contact Ball Bearings:

Angular contact ball bearings are designed to handle both radial and axial loads but primarily excel in supporting combined axial loads and moment loads. They have contact angles that allow them to carry higher thrust loads compared to deep groove ball bearings. Angular contact ball bearings are commonly used in applications such as machine tool spindles, automotive wheels, and pumps where precise axial and radial load support is required.

3. Cylindrical Roller Bearings:

Cylindrical roller bearings have high radial load-carrying capacity and are suitable for applications with heavy radial loads. They have cylindrical rollers as rolling elements and can accommodate axial displacement within the bearing. Cylindrical roller bearings are commonly used in industries such as construction equipment, gearboxes, and large motors.

4. Tapered Roller Bearings:

Tapered roller bearings are designed to handle both radial and axial loads. They have tapered raceways and rollers arranged in a way that allows the bearing to support higher axial loads in one direction. Tapered roller bearings are commonly used in automotive applications, including wheel bearings, transmissions, and differentials, as well as in industrial machinery such as mining equipment and machine tools.

5. Spherical Roller Bearings:

Spherical roller bearings can accommodate high radial loads and moderate axial loads. They have barrel-shaped rolling elements and self-aligning capabilities, allowing them to compensate for misalignment and shaft deflection. Spherical roller bearings are commonly used in heavy-duty applications such as mining, paper mills, and steel mills, where there are significant misalignment or heavy load conditions.

6. Needle Roller Bearings:

Needle roller bearings have cylindrical rollers that are much smaller in diameter compared to other radial bearings. They have a high length-to-diameter ratio, enabling them to handle high radial loads in a compact design. Needle roller bearings are commonly used in applications such as automotive transmissions, motorcycles, and industrial machinery.

7. Thrust Bearings:

Thrust bearings are designed to handle axial loads primarily and are often used in conjunction with radial bearings to support combined axial and radial loads. They come in various designs, including ball thrust bearings, cylindrical thrust bearings, and tapered roller thrust bearings. Thrust bearings are commonly used in automotive, aerospace, and industrial applications that require support for heavy axial loads.

8. Self-Aligning Ball Bearings:

Self-aligning ball bearings have two rows of balls and a spherical outer ring raceway, allowing them to accommodate misalignment between the shaft and housing. They can handle both radial and axial loads and are commonly used in applications where shaft misalignment is expected, such as conveyor systems, textile machinery, and agricultural equipment.

These are just a few examples of specific types of radial bearings, and there are many other variations and specialized designs available for specific applications. Each type of bearing has unique characteristics that make it suitable for particular operating conditions, load requirements, and performance expectations.

Are there specific considerations for choosing radial bearings in applications with varying radial loads or operating conditions?

Choosing radial bearings for applications with varying radial loads or operating conditions requires careful consideration of several factors. The selection process should take into account the specific requirements and challenges posed by the varying loads and operating conditions. Here’s a detailed explanation of the specific considerations for choosing radial bearings in such applications:

1. Load Capacity:

One of the primary considerations is the load capacity of the radial bearing. It is essential to evaluate the expected range of radial loads and ensure that the selected bearing can handle the maximum load without exceeding its capacity. The load capacity of a bearing is typically specified by the manufacturer and is influenced by factors such as bearing size, design, and materials. It is important to choose a bearing with a sufficient load capacity to accommodate the varying radial loads encountered in the application.

2. Dynamic and Static Load Ratings:

The dynamic and static load ratings provided by the bearing manufacturer are crucial for assessing the bearing’s ability to handle varying loads. The dynamic load rating indicates the maximum load a bearing can sustain for a specified number of rotations without experiencing excessive wear or fatigue. The static load rating represents the maximum load the bearing can withstand without permanent deformation. Comparing the expected loads in the application with the dynamic and static load ratings helps ensure that the selected bearing is suitable for the varying radial loads.

3. Bearing Clearance:

Bearing clearance refers to the internal gap between the rolling elements and the raceways. In applications with varying loads, it is important to consider the appropriate bearing clearance. A tighter clearance may be suitable for higher loads as it minimizes internal movement and reduces the risk of excessive wear. On the other hand, a looser clearance may be preferred for lighter loads to ensure smooth operation and minimize friction. It is crucial to consult the bearing manufacturer’s guidelines and recommendations to determine the optimal clearance for the specific application.

4. Lubrication:

Varying radial loads can affect the lubrication requirements of the bearing. Higher loads may result in increased friction and heat generation, necessitating appropriate lubrication to ensure proper operation and prevent premature failure. It is important to select the right type of lubricant and consider factors such as viscosity, temperature range, and compatibility with the bearing materials. In applications with varying loads, periodic monitoring of lubrication conditions and maintenance intervals is essential to ensure optimal lubrication and prevent issues associated with inadequate lubrication.

5. Bearing Design and Materials:

The design and materials of the radial bearing play a significant role in its ability to withstand varying loads and operating conditions. Different bearing designs, such as deep groove ball bearings, cylindrical roller bearings, or tapered roller bearings, have varying load capacities and performance characteristics. The choice of bearing material, such as steel, ceramic, or polymer, can also impact factors such as strength, fatigue resistance, and corrosion resistance. It is important to select a bearing design and material that are suitable for the anticipated loads and operating conditions in the application.

6. Temperature and Environmental Factors:

Varying radial loads can affect the temperature and environmental conditions within the bearing. Higher loads can result in increased heat generation, which may require additional considerations for heat dissipation and thermal management. Similarly, if the application involves exposure to moisture, chemicals, or abrasive particles, it is important to select a bearing with appropriate seals or shields to protect against contamination. Considering the temperature and environmental factors helps ensure the longevity and reliability of the bearing in applications with varying loads.

7. Application-Specific Considerations:

Each application may have unique requirements or constraints that need to be taken into account when selecting radial bearings. Factors such as speed, vibration levels, mounting arrangements, space limitations, and maintenance accessibility should be considered. Consulting with bearing manufacturers or industry experts can provide valuable insights and guidance for choosing the most suitable radial bearings for applications with varying loads and operating conditions.

By carefully evaluating these specific considerations, it is possible to select radial bearings that can reliably and efficiently handle the varying radial loads encountered in the application, ensuring optimal performance and durability.

editor by CX 2024-04-26