Product Description

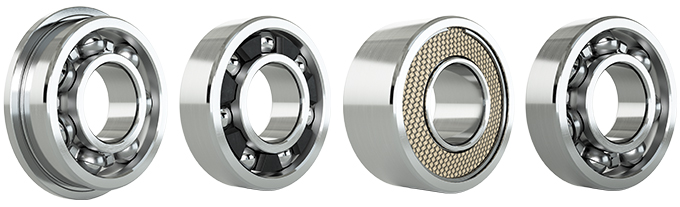

Corrosion-resistant Double Row Radial Spherical Roller Bearing Angular Contact Thrust Roller Bearing

Product Description

Spherical roller thrust bearing

Spherical roller thrust bearings are of spherical shape, and the spherical raceway surface of the housing washer is seIf-aIigned.These bearings are featured by the extremely big axial Ioad carrying capacity and meanwhiIe they can aIso carry certain radiaIIoad.OiIIubricant is comnonIy used while working.

AppIications of these bearings can be found in hydroelectric generators, verticaI motors,propeller axIe of vessels, tower cranes and squeezing presses.

Company Profile

HangZhou HONGSHI MACHINERY AND ELECTRICAL EQUIPMENT CO.,LTD. (formerly HangZhou Hengmai Bearing Co., Ltd.) was established in 2007, and HMMH is our own brand.

HMMH mainly produces spherical roller bearings, pillow block ball bearing, deep groove ball bearings and cylindrical roller bearings. Spherical roller bearing products range from 20mm to 1M, with the main production of crusher bearings 22300 series. Low noise deep groove ball bearings, product accuracy can reach ZV2, ZV3, ZV4, mainly produces motor bearings 6200, 6300 series. pillow block ball bearing, mainly producing UCP, UCF, UCFL, UCFC, UCT series, the products are mainly used in agricultural machine and peeling machine. We also use the bainite quenching process to ensure the hardness of the bearing, using good testing equipment, such as roundness meter, profiler, roughness meter, universal measuring instrument, spectrometer, metallographic microscope to control each detail quality monitoring.

To ensure product quality, we have established a strict quality control system and an experienced team of engineers and after-sales service. From forgings to final products we have a strict quality control system.

Your needs are our production motivation, and your satisfaction is our goal. We are willing to serve our customers with the goal of “Quality First, Service First, Credit First”.

FAQ

1.A:How can I do customized design?

Q:We are request for the drawing with the measurement, material and other speicifcation as details as you can, and for the customized products, our MOQ is 10 pcs per design

2.Q: How can I get a sample?

A: If you only need 1or 2 samples for small size inner weight below 2kgs, we can supply free samples and we have stocks, you can just pay the shipping cost .if you need several design samples, then you should paid the cost with shipping.

3.Q: What package do you usually use?

A: Usually we use single box or tape. Also according to customer’s special requirement.

4.Q:How long do you need for production? Or what’s your production lead time?

A:Usually could be sent our in 2-3 days if in stock for samples. Customized item usually need 14-30 days to produce.

5.Q:How long will you guarantee your quality?

A:We supply test report and quality control photos from materials to finished goods during production.

6.Q:How to do after sale service?

A:Good after-sale service is our promise. Before placing orders, our professional engineer will discuss all technical data and your bearing usage condition and CZPT you what kind of steel materials to fit your products and usage life possible.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Axial Bearing |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the primary functions of radial bearings in machinery and equipment?

Radial bearings play several primary functions in machinery and equipment. They are essential components that provide support, facilitate smooth rotation, and minimize friction in various mechanical systems. Here is a detailed explanation of the primary functions of radial bearings:

1. Load Support:

The primary function of radial bearings is to support loads in machinery and equipment. Radial bearings are designed to withstand radial loads, which are forces that act perpendicular to the shaft’s axis. These loads can include the weight of rotating shafts, belts, pulleys, or other components that exert a radial force. Radial bearings distribute the load evenly across the rolling elements and transmit it to the stationary outer ring. By supporting and distributing the load, radial bearings prevent excessive stress on the rotating components and ensure smooth operation.

2. Facilitating Smooth Rotation:

Radial bearings are crucial for facilitating smooth rotation in machinery and equipment. The rolling elements, such as balls or rollers, in a radial bearing roll between the inner and outer rings. This rolling action reduces friction and enables smooth motion of the rotating shaft or assembly. The low friction provided by radial bearings minimizes energy loss and allows machinery to operate efficiently. By enabling smooth rotation, radial bearings contribute to the overall performance and functionality of the machinery or equipment.

3. Reducing Friction and Power Loss:

Friction is an inherent challenge in mechanical systems that can lead to power loss, heat generation, and premature wear. Radial bearings are designed to minimize friction between the rolling elements and raceways. The rolling motion of the elements reduces sliding friction, resulting in lower power loss and improved energy efficiency. By reducing friction, radial bearings help optimize the performance of machinery and equipment, allowing them to operate with increased reliability and efficiency.

4. Absorbing and Damping Vibrations:

Machinery and equipment can experience vibrations due to various factors, such as imbalances, misalignments, or external forces. Radial bearings play a role in absorbing and damping vibrations within the system. The rolling elements and the bearing structure act as a buffer, absorbing and dissipating vibrations generated during operation. By absorbing vibrations, radial bearings reduce the impact on other components, minimize the risk of damage or excessive wear, and contribute to a smoother and quieter operation of the machinery.

5. Supporting Axial Loads (Limited):

Although radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as thrust or pushing forces. While radial bearings are not specifically optimized for axial loads like dedicated thrust bearings, they can handle moderate axial loads that may be present in certain applications. However, it is important to consider the axial load capacity of the specific radial bearing and ensure that the applied axial load remains within its limits.

6. Enabling Compact and Space-Efficient Designs:

Radial bearings offer the advantage of enabling compact and space-efficient designs in machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions and tighter tolerances. By using radial bearings, machinery and equipment can be more compact, lightweight, and efficient without compromising their performance or load-carrying capabilities. This space-saving feature is particularly valuable in applications where space constraints or weight considerations are critical factors.

7. Providing Mechanical Stability:

Radial bearings contribute to the mechanical stability of machinery and equipment. They help maintain the proper alignment of rotating components, preventing excessive vibration, misalignment, or skewing. The precise fit and alignment of the bearing components ensure that the rotating shaft or assembly operates within the desired tolerances. This mechanical stability provided by radial bearings is crucial for the overall performance, reliability, and longevity of the machinery or equipment.

In summary, the primary functions of radial bearings in machinery and equipment include load support, facilitating smooth rotation, reducing friction and power loss, absorbing and damping vibrations, supporting limited axial loads, enabling compact designs, and providing mechanical stability. Radial bearings play a critical role in optimizing the performance, reliability, and efficiency of various mechanical systems.

Can you provide examples of industries or equipment that frequently use radial bearings?

Yes, radial bearings are widely used in various industries and equipment where rotational motion is involved. They are essential components in many applications that require efficient and reliable operation. Here are some examples of industries and equipment that frequently utilize radial bearings:

1. Automotive Industry:

The automotive industry extensively uses radial bearings in various components such as engines, transmissions, wheel hubs, suspension systems, and electric motors. Radial bearings ensure smooth and reliable rotation in these applications, contributing to the overall performance and durability of vehicles.

2. Industrial Machinery and Equipment:

Radial bearings find extensive use in a wide range of industrial machinery and equipment. This includes pumps, compressors, fans, motors, conveyors, machine tools, printing presses, textile machinery, and packaging equipment. Radial bearings in these applications support rotational motion, reduce friction, and ensure precise operation, thereby enhancing productivity and reliability.

3. Aerospace Industry:

In the aerospace industry, radial bearings are vital for various applications, including aircraft engines, landing gear, control systems, and helicopter rotor systems. These bearings provide critical support for rotational motion under demanding conditions, such as high speeds, extreme temperatures, and heavy loads.

4. Power Generation:

Power generation facilities, such as thermal power plants, hydroelectric plants, and wind turbines, rely on radial bearings in turbines, generators, and other rotating machinery. Radial bearings ensure smooth rotation and efficient power generation by minimizing friction and supporting heavy loads in these critical energy production systems.

5. Heavy Equipment and Construction:

In the heavy equipment and construction industry, radial bearings are used in equipment like excavators, cranes, loaders, bulldozers, and concrete mixers. These bearings enable smooth operation and support the heavy loads encountered during construction and earthmoving activities.

6. Mining and Quarrying:

In mining and quarrying operations, radial bearings are employed in machinery such as crushers, screens, mills, and conveyors. These bearings withstand harsh conditions, heavy loads, and high speeds, ensuring reliable performance in demanding environments.

7. Railway and Transportation:

Radial bearings play a crucial role in the railway and transportation industry. They are used in applications such as locomotives, passenger trains, freight trains, tramways, and metro systems. These bearings support the rotational motion of wheels, axles, and drive systems, ensuring safe and efficient transportation.

8. Medical and Scientific Equipment:

Radial bearings are utilized in various medical and scientific equipment, including centrifuges, laboratory instruments, imaging devices, and precision equipment. These bearings provide smooth rotation, accuracy, and stability required for critical research, diagnostics, and medical procedures.

9. Marine and Offshore Industry:

Radial bearings are used in marine and offshore applications, such as ship propulsion systems, marine winches, rudders, and offshore drilling equipment. These bearings withstand corrosive environments, high loads, and challenging operating conditions encountered in marine and offshore operations.

10. Renewable Energy:

In the renewable energy sector, radial bearings are employed in wind turbines, solar tracking systems, and tidal energy converters. These bearings support the rotation of turbine blades, solar panels, and other components, ensuring efficient energy generation from renewable sources.

These examples highlight the broad range of industries and equipment that frequently rely on radial bearings. The versatility, reliability, and performance of radial bearings make them indispensable components in numerous applications where rotational motion is essential.

Can you describe the various types of seals and shields used with radial bearings for contamination prevention?

Seals and shields are commonly used with radial bearings to prevent contamination and protect the bearing internals from external particles, moisture, and other contaminants. They help maintain the integrity of the lubricant and extend the service life of the bearing. Here’s a detailed description of the various types of seals and shields used with radial bearings:

1. Contact Seals:

Contact seals, also known as lip seals or radial lip seals, are designed to make direct contact with the inner ring of the bearing. They consist of a flexible sealing lip that forms a barrier between the inner and outer ring of the bearing. Contact seals effectively prevent the entry of contaminants into the bearing by creating a tight seal. They are commonly made of rubber or elastomeric materials and provide effective sealing against solid particles, liquids, and gases. Contact seals offer good contamination prevention but may generate higher friction and heat compared to non-contact seals.

2. Non-Contact Seals:

Non-contact seals, also known as labyrinth seals or gap seals, do not make direct contact with the inner ring of the bearing. Instead, they rely on a series of barriers or labyrinth-like structures to create a tortuous path that prevents the entry of contaminants. Non-contact seals provide effective protection against solid particles, such as dust and dirt, while allowing for minimal friction and heat generation. They are commonly made of metal or plastic and are suitable for high-speed applications where reduced friction is critical.

3. Shielded Bearings:

Shielded bearings, also known as metal shields or ZZ bearings, are equipped with metallic shields that cover the outer surface of the bearing. These shields are usually made of steel and provide a physical barrier against contaminants. Shielded bearings are designed to prevent the entry of larger particles, such as dirt and debris, while allowing for the circulation of lubricating grease within the bearing. However, they do not provide a complete seal and may not be suitable for applications where protection against moisture or fine particles is required.

4. Rubber Seals:

Rubber seals, also known as rubber contact seals or RS bearings, are similar to contact seals but are made entirely of rubber or elastomeric materials. They provide effective sealing against contaminants, including solid particles, liquids, and gases. Rubber seals offer good contamination prevention and are more flexible than other sealing options, allowing for better adaptability to varying operating conditions. They are commonly used in applications where protection against moisture, dust, and other fine particles is essential.

5. Felt Seals:

Felt seals are made of compressed or woven felt material and are used primarily in low-speed applications. They provide a barrier against larger particles and help retain lubricating oil or grease within the bearing. Felt seals are relatively simple and cost-effective solutions for contamination prevention. However, they may not offer the same level of protection as other sealing options and may require regular lubrication to maintain their effectiveness.

6. Combination Seals:

Combination seals utilize a combination of different sealing mechanisms to provide enhanced contamination prevention. These seals often incorporate both contact and non-contact elements to create an effective barrier against various contaminants. Combination seals are designed to address specific application requirements, providing a balance between sealing effectiveness, friction, heat generation, and other performance factors.

7. Additional Features:

Some seals and shields may incorporate additional features to enhance contamination prevention. For example, seals may include dust lips or auxiliary lips to provide extra protection against fine particles. Shields may have gap fillers or flingers to deflect contaminants away from the bearing. These additional features help improve the sealing effectiveness and contribute to extended bearing life.

When selecting seals and shields for radial bearings, it is essential to consider the specific application requirements, operating conditions, and the level of contamination protection needed. Manufacturers typically provide guidelines and recommendations regarding the appropriate sealing options for their bearings to ensure optimal performance and reliability.

editor by CX 2024-05-07