Product Description

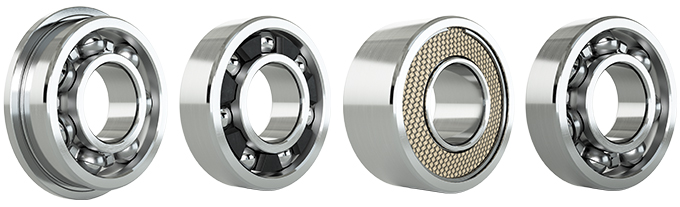

Bearing Heavy duty roller bearing Stainless Steel Radial Insert Ball Bearing SSUC208 Pillow Block Bearing with SS304 material

Parameters:

| Product Name | Pillow Block Bearing |

| Material | Chrome Steel, GCR15,Cast Iron,Stainless Steel |

| Type | UC,UK,SA,SB,UEL Series Insert bearing, UCF,UCP,UCT,UCFL,UCPA,UCFC,UCFA,UCFB,UCPH Series Insert Bearing With Pillow Block |

| Size | d:3-110mm,D:9-240mm |

| Grade | PO,P6,P5,P4,P2 |

| Shield | ZZ ,2RS, OPEN |

| Used For | Mining, metallurgy, agriculture, chemical industry, textile, printing and dyeing, conveying machinery, etc. |

| Warranty | 1 year |

| Brand | R&Z or OEM |

| Packing | According to the buyer requests for packaging |

Specification:

| Bearing No. | Weight | UCP | UCF | UCT | UCFL | UCPA | UCFA | UCPH |

| KG | ||||||||

| UC201 | 0.16 | UCP201 | UCF201 | UCT201 | UCFL201 | UCPA201 | UCFA201 | UCPH201 |

| UC202 | 0.18 | UCP202 | UCF202 | UCT202 | UCFL202 | UCPA202 | UCFA202 | UCPH202 |

| UC203 | 0.19 | UCP203 | UCF203 | UCT203 | UCFL203 | UCPA203 | UCFA203 | UCPH203 |

| UC204 | 0.21 | UCP204 | UCF204 | UCT204 | UCFL204 | UCPA204 | UCFA204 | UCPH204 |

| UC205 | 0.29 | UCP205 | UCF205 | UCT205 | UCFL205 | UCPA205 | UCFA205 | UCPH205 |

| UC206 | 0.31 | UCP206 | UCF206 | UCT206 | UCFL206 | UCPA206 | UCFA206 | UCPH206 |

| UC207 | 0.49 | UCP207 | UCF207 | UCT207 | UCFL207 | UCPA207 | UCFA207 | UCPH207 |

| UC208 | 0.63 | UCP208 | UCF208 | UCT208 | UCFL208 | UCPA208 | UCFA208 | UCPH208 |

| UC209 | 0.68 | UCP209 | UCF209 | UCT209 | UCFL209 | UCPA209 | UCFA209 | UCPH209 |

| UC210 | 0.79 | UCP210 | UCF210 | UCT210 | UCFL210 | UCPA210 | UCFA210 | UCPH210 |

| UC211 | 1.04 | UCP211 | UCF211 | UCT211 | UCFL211 | UCPA211 | UCFA211 | UCPH211 |

| UC212 | 1.47 | UCP212 | UCF212 | UCT212 | UCFL212 | UCPA212 | UCFA212 | UCPH212 |

| UC213 | 1.73 | UCP213 | UCF213 | UCT213 | UCFL213 | UCPA213 | UCFA213 | UCPH213 |

| UC214 | 2.08 | UCP214 | UCF214 | UCT214 | UCFL214 | UCPA214 | UCFA214 | UCPH214 |

| UC215 | 2.25 | UCP215 | UCF215 | UCT215 | UCFL215 | UCPA215 | UCFA215 | UCPH215 |

| UC216 | 2.86 | UCP216 | UCF216 | UCT216 | UCFL216 | UCPA216 | UCFA216 | UCPH216 |

| UC217 | 3.42 | UCP217 | UCF217 | UCT217 | UCFL217 | UCPA217 | UCFA217 | UCPH217 |

| UC218 | 4.4 | UCP218 | UCF218 | UCT218 | UCFL218 | UCPA218 | UCFA218 | UCPH218 |

| Bearing No. | Weight | UCP | UCF | UCT | UCFL | UCPA | UCFC | UCPH |

| kg | ||||||||

| UC 305 | 0.45 | UCP305 | UCF305 | UCT305 | UCFL305 | UCPA305 | UCFC305 | UCPH305 |

| UC 306 | 0.57 | UCP306 | UCF306 | UCT306 | UCFL306 | UCPA306 | UCFC306 | UCPH306 |

| UC 307 | 0.72 | UCP307 | UCF307 | UCT307 | UCFL307 | UCPA307 | UCFC307 | UCPH307 |

| UC 308 | 1.00 | UCP308 | UCF308 | UCT308 | UCFL308 | UCPA308 | UCFC308 | UCPH308 |

| UC 309 | 1.30 | UCP309 | UCF309 | UCT309 | UCFL309 | UCPA309 | UCFC309 | UCPH309 |

| UC 310 | 1.67 | UCP310 | UCF310 | UCT310 | UCFL310 | UCPA310 | UCFC310 | UCPH310 |

| UC 311 | 2.10 | UCP311 | UCF311 | UCT311 | UCFL311 | UCPA311 | UCFC311 | UCPH311 |

| UC 312 | 2.62 | UCP312 | UCF312 | UCT312 | UCFL312 | UCPA312 | UCFC312 | UCPH312 |

| UC 313 | 3.19 | UCP313 | UCF313 | UCT313 | UCFL313 | UCPA313 | UCFC313 | UCPH313 |

| UC 314 | 3.88 | UCP314 | UCF314 | UCT314 | UCFL314 | UCPA314 | UCFC314 | UCPH314 |

| UC 315 | 4.68 | UCP315 | UCF315 | UCT315 | UCFL315 | UCPA315 | UCFC315 | UCPH315 |

| UC 316 | 5.50 | UCP316 | UCF316 | UCT316 | UCFL316 | UCPA316 | UCFC316 | UCPH316 |

| UC 317 | 6.67 | UCP317 | UCF317 | UCT317 | UCFL317 | UCPA317 | UCFC317 | UCPH317 |

| UC 318 | 7.50 | UCP318 | UCF318 | UCT318 | UCFL318 | UCPA318 | UCFC318 | UCPH318 |

| UC 319 | 8.80 | UCP319 | UCF319 | UCT319 | UCFL319 | UCPA319 | UCFC319 | UCPH319 |

| UC 320 | 10.94 | UCP320 | UCF320 | UCT320 | UCFL320 | UCPA320 | UCFC320 | UCPH320 |

| UC 322 | 14.50 | UCP322 | UCF322 | UCT322 | UCFL322 | UCPA322 | UCFC322 | UCPH322 |

| UC 324 | 18.75 | UCP324 | UCF324 | UCT324 | UCFL324 | UCPA324 | UCFC324 | UCPH324 |

Pillow block bearing description:

Other hot sale products

Application

Mining, metallurgy, agriculture, chemical industry, textile, printing and dyeing, conveying machinery, etc.

Our package

* Industrial package+outer carton+pallets

* single box+outer carton+pallets

* Tube package+middle box+outer carton+pallets

* According to your requirements

FAQ:

SAMPLES

1.Samples quantity: 1-10 pcs are available.

2.Free samples: It depends on the model NO., material and quantity. Some of the bearings samples need client to pay

samples charge and shipping cost.

CUSTOMIZED

The customized LOGO or drawing is acceptable for us.

MOQ

1.MOQ: 10 pcs mix different standard bearings.

2.MOQ: 2000 pcs customized your brand bearings.

OEM POLICY

1.We can printing our brand (logo,artwork) on the shield or make your own brand on the shield.

2.We can custom your packaging according to your design

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Separated |

| Feature: | Low Temperature, Corrosion Resistant, High Speed |

| Rows Number: | Single |

| Raceway: | No |

| Material: | Cast Iron |

| Samples: |

US$ 0.01/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the key advantages of using radial bearings in various industrial applications?

Radial bearings offer several key advantages that make them highly advantageous for various industrial applications. These advantages contribute to improved performance, reliability, and efficiency in machinery and equipment. Here are the key advantages of using radial bearings:

1. Load Support:

Radial bearings provide excellent load support, distributing and carrying radial loads in machinery and equipment. They are designed to handle the weight of rotating components, belts, pulleys, and other radial forces. By effectively supporting the loads, radial bearings minimize stress on the rotating components, ensuring smooth operation and preventing premature wear or damage.

2. Friction Reduction:

Radial bearings are designed to minimize friction between the rolling elements and raceways, resulting in reduced energy loss and improved efficiency. The rolling action of the elements reduces sliding friction, allowing machinery to operate with less resistance and lower power consumption. By reducing friction, radial bearings help optimize the performance of industrial applications, leading to increased productivity and energy savings.

3. Smooth Operation:

With their ability to facilitate smooth rotation, radial bearings contribute to smooth and precise operation in industrial applications. The rolling elements, such as balls or rollers, enable low-friction motion, ensuring that rotating shafts or assemblies move with minimal vibrations or jerks. This smooth operation enhances the overall performance, accuracy, and reliability of machinery and equipment.

4. Noise and Vibration Reduction:

Radial bearings play a crucial role in reducing noise and vibration in industrial applications. The rolling elements and bearing structure absorb and dampen vibrations generated during operation, minimizing their transmission to other components. By reducing noise and vibration, radial bearings contribute to a quieter and more comfortable working environment, as well as extending the lifespan of the equipment by reducing the risk of damage caused by excessive vibrations.

5. Versatility and Adaptability:

Radial bearings are highly versatile and adaptable to a wide range of industrial applications. They are available in various sizes, designs, and materials, allowing engineers to select the most suitable bearing for specific operating conditions and requirements. Radial bearings can withstand different speeds, temperature ranges, and environmental conditions, making them well-suited for diverse industrial applications across various industries.

6. Compact Design:

Radial bearings enable compact and space-efficient designs in industrial machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions, reduced weight, and tighter tolerances. This compact design feature is particularly crucial in applications where space constraints or weight considerations are significant factors.

7. Longevity and Reliability:

Radial bearings are engineered to provide long service life and reliable performance in demanding industrial environments. They are designed with high-quality materials and advanced manufacturing techniques to withstand heavy loads, high speeds, and harsh operating conditions. Radial bearings undergo rigorous testing and quality control measures to ensure their durability and reliability, minimizing downtime and maintenance costs in industrial applications.

8. Cost-Effectiveness:

Radial bearings offer cost-effectiveness in industrial applications. Their ability to reduce friction, minimize power loss, and provide reliable performance contributes to improved energy efficiency and reduced operating costs. Additionally, the long service life and low maintenance requirements of radial bearings contribute to overall cost savings over the lifespan of the machinery or equipment.

In summary, the key advantages of using radial bearings in various industrial applications include load support, friction reduction, smooth operation, noise and vibration reduction, versatility, compact design, longevity and reliability, and cost-effectiveness. These advantages make radial bearings an essential component for enhancing performance, efficiency, and reliability in industrial machinery and equipment.

What is the impact of proper lubrication on the performance and lifespan of radial bearings?

Proper lubrication plays a crucial role in the performance and lifespan of radial bearings. It is essential to provide adequate lubrication to minimize friction, reduce wear, and ensure reliable operation. Here’s a detailed explanation of the impact of proper lubrication on the performance and lifespan of radial bearings:

1. Friction Reduction:

Proper lubrication forms a thin film of lubricant between the rolling elements and raceways of the bearing. This lubricating film reduces friction and minimizes the resistance to rotation, allowing the bearing to operate smoothly. Reduced friction results in lower energy consumption, decreased heat generation, and improved overall efficiency of the bearing system.

2. Wear Prevention:

Effective lubrication helps prevent wear and damage to the bearing surfaces. The lubricant forms a protective layer that separates the rolling elements from the raceways, preventing direct metal-to-metal contact. This separation minimizes wear, surface fatigue, and the risk of premature bearing failure. Proper lubrication significantly extends the lifespan of radial bearings by preserving their working surfaces.

3. Temperature Control:

Lubrication plays a critical role in controlling the operating temperature of radial bearings. The lubricant absorbs and dissipates heat generated during operation, preventing excessive temperature rise. Adequate lubrication helps maintain the bearing within the optimal temperature range, reducing the risk of thermal damage and preserving the integrity of the bearing components.

4. Contamination Protection:

Proper lubrication forms a barrier against contaminants such as dirt, dust, moisture, and particles. The lubricant acts as a protective shield, preventing these contaminants from entering the bearing and causing damage. Effective lubrication helps maintain the cleanliness of the bearing, reducing the risk of abrasive wear, corrosion, and other forms of contamination-induced failure.

5. Corrosion Prevention:

Lubrication helps prevent corrosion and rust formation on the bearing surfaces. The lubricant forms a protective film that acts as a barrier, preventing moisture and corrosive agents from reaching the metal surfaces. By inhibiting corrosion, proper lubrication enhances the longevity and reliability of radial bearings, particularly in demanding environments or applications exposed to moisture and corrosive substances.

6. Noise and Vibration Reduction:

Effective lubrication contributes to reducing noise and vibration levels in radial bearings. The lubricant absorbs and dampens the vibrations generated during operation, resulting in smoother and quieter bearing performance. Proper lubrication helps minimize noise pollution, enhances user comfort, and improves the overall operation of machinery and equipment.

7. Load Capacity Enhancement:

Appropriate lubrication can enhance the load-carrying capacity of radial bearings. The lubricant’s lubricating properties and film thickness help distribute the applied loads evenly across the bearing surfaces, reducing stress concentrations. This allows the bearing to support higher loads and handle heavier operating conditions without compromising its performance or lifespan.

8. Reliability and Longevity:

Overall, proper lubrication significantly enhances the reliability and longevity of radial bearings. It minimizes wear, reduces friction, prevents damage, controls temperature, protects against contamination, inhibits corrosion, reduces noise and vibration, and improves load-carrying capacity. By ensuring optimal lubrication conditions, the performance and lifespan of radial bearings are maximized, leading to improved equipment uptime, reduced maintenance requirements, and increased operational efficiency.

In conclusion, proper lubrication is essential for achieving optimal performance, longevity, and reliability of radial bearings. It minimizes friction, reduces wear, controls temperature, protects against contamination and corrosion, and enhances load-carrying capacity. Regular monitoring and maintenance of lubrication conditions are crucial to ensure the continued smooth operation and extended lifespan of radial bearings.

Are there specific considerations for choosing radial bearings in applications with varying radial loads or operating conditions?

Choosing radial bearings for applications with varying radial loads or operating conditions requires careful consideration of several factors. The selection process should take into account the specific requirements and challenges posed by the varying loads and operating conditions. Here’s a detailed explanation of the specific considerations for choosing radial bearings in such applications:

1. Load Capacity:

One of the primary considerations is the load capacity of the radial bearing. It is essential to evaluate the expected range of radial loads and ensure that the selected bearing can handle the maximum load without exceeding its capacity. The load capacity of a bearing is typically specified by the manufacturer and is influenced by factors such as bearing size, design, and materials. It is important to choose a bearing with a sufficient load capacity to accommodate the varying radial loads encountered in the application.

2. Dynamic and Static Load Ratings:

The dynamic and static load ratings provided by the bearing manufacturer are crucial for assessing the bearing’s ability to handle varying loads. The dynamic load rating indicates the maximum load a bearing can sustain for a specified number of rotations without experiencing excessive wear or fatigue. The static load rating represents the maximum load the bearing can withstand without permanent deformation. Comparing the expected loads in the application with the dynamic and static load ratings helps ensure that the selected bearing is suitable for the varying radial loads.

3. Bearing Clearance:

Bearing clearance refers to the internal gap between the rolling elements and the raceways. In applications with varying loads, it is important to consider the appropriate bearing clearance. A tighter clearance may be suitable for higher loads as it minimizes internal movement and reduces the risk of excessive wear. On the other hand, a looser clearance may be preferred for lighter loads to ensure smooth operation and minimize friction. It is crucial to consult the bearing manufacturer’s guidelines and recommendations to determine the optimal clearance for the specific application.

4. Lubrication:

Varying radial loads can affect the lubrication requirements of the bearing. Higher loads may result in increased friction and heat generation, necessitating appropriate lubrication to ensure proper operation and prevent premature failure. It is important to select the right type of lubricant and consider factors such as viscosity, temperature range, and compatibility with the bearing materials. In applications with varying loads, periodic monitoring of lubrication conditions and maintenance intervals is essential to ensure optimal lubrication and prevent issues associated with inadequate lubrication.

5. Bearing Design and Materials:

The design and materials of the radial bearing play a significant role in its ability to withstand varying loads and operating conditions. Different bearing designs, such as deep groove ball bearings, cylindrical roller bearings, or tapered roller bearings, have varying load capacities and performance characteristics. The choice of bearing material, such as steel, ceramic, or polymer, can also impact factors such as strength, fatigue resistance, and corrosion resistance. It is important to select a bearing design and material that are suitable for the anticipated loads and operating conditions in the application.

6. Temperature and Environmental Factors:

Varying radial loads can affect the temperature and environmental conditions within the bearing. Higher loads can result in increased heat generation, which may require additional considerations for heat dissipation and thermal management. Similarly, if the application involves exposure to moisture, chemicals, or abrasive particles, it is important to select a bearing with appropriate seals or shields to protect against contamination. Considering the temperature and environmental factors helps ensure the longevity and reliability of the bearing in applications with varying loads.

7. Application-Specific Considerations:

Each application may have unique requirements or constraints that need to be taken into account when selecting radial bearings. Factors such as speed, vibration levels, mounting arrangements, space limitations, and maintenance accessibility should be considered. Consulting with bearing manufacturers or industry experts can provide valuable insights and guidance for choosing the most suitable radial bearings for applications with varying loads and operating conditions.

By carefully evaluating these specific considerations, it is possible to select radial bearings that can reliably and efficiently handle the varying radial loads encountered in the application, ensuring optimal performance and durability.

editor by CX 2024-05-07