Product Description

Welcome to choose KORTON INDUSTRIAL LIMITED.

NO 1. our adwantages:

1. 14 years bearing products manufacturing and 4 years exporting experiences.

2. OEM order and non-standard bearing order can be accepted.

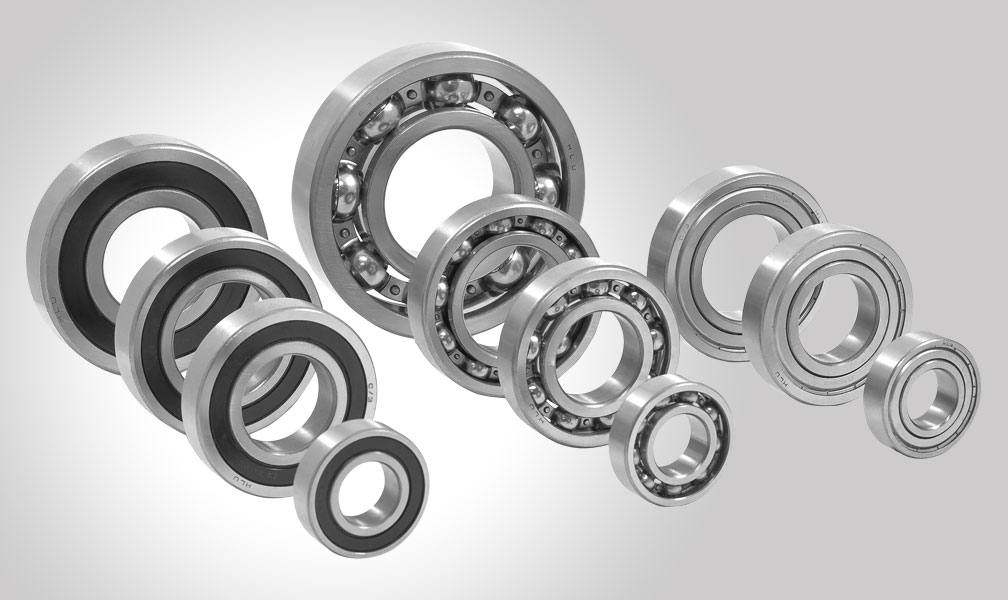

3. Our main bearing products include Deep groove ball bearings, tapered roller bearings, cylindrical rollerbearings, spherical ball bearings, spherical roller bearings, angular contact bearings, needle roller bearings, thrust ball bearings, spherical plain bearings, spherical bearings, automotive bearings pump bearings, and many nonstandard bearings are also in our product range.

4. Sample available

NO 2. Description: Needle Bearing

| 1 | Drawn Cup Needle Bearing | HK, BK |

| 2 | Needle Bearing with Inner Ring | NA, NKI |

| 3 | Needle Bearing without Inner Ring | NK, RNA |

| 4 | Full Complement Needle Bearing | NAV |

| 5 | Radial Needle Roller and Cage Assemblies | K, KK |

| 6 | Thrust Needle Roller and Cage Assemblies | AXK, AS |

NO 3. OEM all brand bearing

1. deep groove ball bearing 6000,6200,6300,6400,61800,61900,Z,RS,ZZ,2RS

2. spherical roller bearing 22200,22300,23000,24000,23100,24100,CA,CC,E,W33

3. cylindrical roller bearing N,NU,NJ,NN,NUP,E,ECP,ECM,ECJ

4. taper roller bearing 35710,30300,32200,32300,31300,32000

5. Aligning ball bearing 1200,1300,2200,2300,

6. needle roller bearing NA,NAV,NK,NKI,RNA,NK,RNAV,ZKLF,ZKLN,ZARF,ZARN

7. thrust ball bearing 51100,51200,51300,51400,E,M

8. angular contact ball bearing7000,7100,7200,7300,AC,BECBM,C

9. spherical plain bearing GE,GEG,GEEW,U,UC,UG,GX,GAC,SA,SABP

10.Wheel hub bearing /ceramic bearing/plastic bearing/lazy susan bearing

NO 4. Needle Bearing Specification:

| Seals Types | OPEN |

| Vibration Level | Z1V1,Z2V2,Z3V3 |

| Clearance | C2,C0,C3,C4,C5 |

| Tolerance Codes | ABEC-1,ABEC-3,ABEC-5 |

| Materral | GCr15-China/AISI52100-USA/Din100Cr6-Germany |

| MOQ | 1Set at least |

| Delivery Time | 5-15 days after contract |

| Payment Terms | TT/PAPAL/WESTERN UNION |

| Package | Tube package+outer carton+pallets;Single box+outer carton+pallets; Tube packge+middle box+outer carton+pallets;According to your requirement |

NO 5. Needle Bearing Models and Size:

| Bearing Designation | Boundary Dimensions | Basic Load Ratings | Limiting Speed | ||||

| HK | BK | Fw | D | C | Cr Dynamic | Cor Static | Oil |

| mm | mm | mm | Nm | Nm | |||

| HK0306TN | BK0306TN | 3 | 6.5 | 6 | 1320 | 950 | 60000 |

| HK0408TN | BK0408TN | 4 | 8 | 8 | 1540 | 1070 | 40000 |

| HK0509 | BK0509 | 5 | 9 | 9 | 2200 | 1790 | 36000 |

| HK0608 | – | 6 | 10 | 8 | 1830 | 1550 | 32000 |

| HK0609 | BK0609 | 6 | 10 | 9 | 2650 | 2400 | 3000 |

| HK0708 | – | 7 | 11 | 8 | 2800 | 2150 | 27000 |

| HK0709 | BK0709 | 7 | 11 | 9 | 2800 | 2150 | 27000 |

| HK0808 | BK0808 | 8 | 12 | 8 | 2550 | 2400 | 21000 |

| HK571 | BK571 | 8 | 12 | 10 | 3700 | 3450 | 21000 |

| HK08×14×10 | – | 8 | 14 | 10 | 3800 | 3950 | 25000 |

| HK08×14×12 | – | 8 | 14 | 12 | 4100 | 4320 | 25000 |

| HK571 | BK571 | 9 | 13 | 10 | 4050 | 4250 | 25000 |

| HK571 | – | 9 | 13 | 12 | 5000 | 6000 | 25000 |

| HK1571 | BK1571 | 10 | 14 | 10 | 3900 | 4800 | 19000 |

| HK1012 | BK1012 | 10 | 14 | 10 | 5000 | 6300 | 19000 |

| HK1015 | – | 10 | 14 | 15 | 6700 | 7800 | 19000 |

| HK10×16×10 | – | 10 | 16 | 10 | 6800 | 8800 | 18000 |

| HK10×16×12 | – | 10 | 16 | 12 | 6800 | 8800 | 18000 |

| HK10×16×15 | – | 10 | 16 | 15 | 6800 | 8800 | 19000 |

| HK1210 | BK1210 | 12 | 16 | 10 | 4150 | 5800 | 19000 |

| HK1212 | BK1212 | 12 | 18 | 12 | 3800 | 5100 | 15000 |

| HK12×17×12 | – | 12 | 17 | 12 | 5100 | 7000 | 15000 |

| HK12×17×15 | – | 12 | 17 | 15 | 5100 | 7000 | 15000 |

| HK12×17×18 | – | 12 | 17 | 18 | 5100 | 7000 | 15000 |

| HK12×18×12 | BK12×18×12 | 12 | 18 | 12 | 550 | 6300 | 17000 |

| HK1312 | BK1312 | 13 | 19 | 12 | 6200 | 7100 | 17000 |

| HK13.5×20×12 | – | 13.5 | 20 | 12 | 6250 | 7590 | 16000 |

| HK1412 | – | 14 | 20 | 12 | 6800 | 7500 | 14000 |

| HK1416 | – | 14 | 20 | 16 | 7300 | 9000 | 14000 |

| HK15×20×12 | – | 15 | 20 | 12 | 5800 | 6000 | 14000 |

| HK15×20×16 | – | 15 | 20 | 16 | 6000 | 6200 | 14000 |

| HK15×20×20 | – | 15 | 20 | 20 | 6100 | 6400 | 14000 |

| HK1512 | BK1512 | 15 | 21 | 12 | 7000 | 8400 | 14000 |

| HK1514 | – | 15 | 21 | 14 | 8500 | 10400 | 13000 |

| HK1515 | – | 15 | 21 | 15 | 9100 | 11400 | 13000 |

| HK1516 | BK1516 | 15 | 21 | 16 | 9800 | 11400 | 14000 |

| HK1522 | – | 15 | 21 | 22 | 10400 | 16500 | 14000 |

| HK15×22×12 | – | 15 | 22 | 12 | 14300 | 18400 | 13000 |

| HK1612 | BK1612 | 16 | 22 | 12 | 7100 | 9200 | 14000 |

| HK1614 | – | 16 | 22 | 14 | 8800 | 9900 | 12000 |

| HK1616 | BK1616 | 16 | 22 | 16 | 15710 | 14300 | 14000 |

| HK1622 | – | 16 | 22 | 22 | 11100 | 17400 | 14000 |

| HK1712 | – | 17 | 23 | 12 | 6900 | 9300 | 13000 |

| HK1714 | – | 17 | 23 | 14 | 6800 | 15710 | 10000 |

| HK1716 | – | 17 | 23 | 16 | 8500 | 12500 | 10000 |

| HK1718 | – | 17 | 23 | 18 | 9500 | 10600 | 10000 |

| HK17×25×14 | – | 17 | 25 | 14 | 13100 | 147000 | 10000 |

| HK17×25×18 | – | 17 | 25 | 18 | 9500 | 10600 | 11000 |

| HK1812 | – | 18 | 24 | 12 | 7100 | 9900 | 12000 |

| HK1816 | BK1816 | 18 | 24 | 16 | 10600 | 15300 | 12000 |

| HK2571 | – | 20 | 26 | 10 | 5900 | 7200 | 10000 |

| HK2014 | – | 20 | 26 | 14 | 9700 | 18100 | 9000 |

| HK2016 | BK2016 | 20 | 26 | 16 | 11700 | 29100 | 10000 |

| HK2018 | – | 20 | 26 | 18 | 7900 | 12800 | 9000 |

| HK2571 | – | 20 | 26 | 20 | 13700 | 24000 | 10000 |

| HK2030 | – | 20 | 26 | 30 | 21800 | 40000 | 15710 |

| HK20×27×20 | – | 20 | 27 | 20 | 26300 | 47800 | 9900 |

| HK2210 | – | 22 | 28 | 10 | 7200 | 9500 | 1571 |

| HK2212 | BK2212 | 22 | 28 | 12 | 8100 | 10400 | 1571 |

| HK22×29×30 | – | 22 | 29 | 30 | 19400 | 33100 | 9000 |

| HK2512 | BK2512 | 25 | 32 | 12 | 10000 | 14200 | 9000 |

| HK2525 | BK2525 | 25 | 32 | 25 | 22200 | 36700 | 9000 |

| HK2816 | BK2816 | 28 | 35 | 16 | 15400 | 22500 | 8700 |

| HK2820 | BK2820 | 28 | 35 | 20 | 18900 | 32000 | 8700 |

| HK3012 | BK3012 | 30 | 37 | 12 | 15710 | 16200 | 8100 |

| HK3571 | BK3571 | 30 | 37 | 20 | 19700 | 33500 | 8100 |

| HK3224 | – | 32 | 39 | 24 | 25500 | 5200 | 7300 |

| HK3516 | BK3516 | 35 | 42 | 16 | 15700 | 27500 | 7100 |

| HK4012 | BK4012 | 40 | 47 | 12 | 14000 | 24300 | 6300 |

| HK4512 | BK4512 | 45 | 52 | 12 | 12900 | 22500 | 5800 |

| HK5571 | BK5571 | 50 | 58 | 20 | 28000 | 60000 | 5300 |

| HK6012 | BK6012 | 60 | 68 | 12 | 12400 | 29000 | 4100 |

| Shaft Dia | Unit No. | Dimensions (mm) | Basic Load Ratings | Limiting speed | Weight | ||||||

| mm | d | F | D | B | r min | S | C KN | C0 KN | r/min | g | |

| 10 | NA4900 | 10 | 14 | 22 | 13 | 0.3 | 0.5 | 8.5 | 9.2 | 20000 | 23 |

| 12 | NA4901 | 12 | 16 | 24 | 13 | 0.3 | 0.5 | 9.4 | 10.9 | 17000 | 26 |

| 15 | NA4902 | 15 | 20 | 28 | 13 | 0.3 | 0.5 | 10.6 | 13.6 | 14000 | 34 |

| 17 | NA4903 | 17 | 22 | 30 | 13 | 0.3 | 0.5 | 11 | 14.6 | 12000 | 37 |

| 20 | NA4904 | 20 | 25 | 37 | 17 | 0.3 | 0.8 | 21 | 25.5 | 10000 | 141 |

| 22 | NA49/22 | 22 | 28 | 39 | 17 | 0.3 | 0.8 | 22.8 | 29.5 | 9500 | 80 |

| 25 | NA4905 | 25 | 30 | 42 | 17 | 0.3 | 0.8 | 23.6 | 31.5 | 9500 | 88 |

| 28 | NA49/28 | 28 | 32 | 45 | 17 | 0.3 | 0.8 | 24.4 | 33.5 | 8500 | 97.7 |

| 30 | NA4906 | 30 | 35 | 47 | 17 | 0.3 | 0.8 | 25 | 35.5 | 8000 | 101 |

| 32 | NA49/32 | 32 | 40 | 52 | 20 | 0.6 | 0.8 | 30.5 | 47.5 | 7000 | 158 |

| 35 | NA4907 | 35 | 42 | 55 | 20 | 0.6 | 0.8 | 31.5 | 50 | 7000 | 170 |

| 40 | NA4908 | 40 | 48 | 62 | 22 | 0.6 | 1 | 43 | 67 | 6000 | 230 |

| 45 | NA4909 | 45 | 52 | 68 | 22 | 0.6 | 1 | 45 | 73 | 8500 | 5500 |

| 50 | NA4910 | 50 | 58 | 72 | 22 | 0.6 | 1 | 47 | 80 | 5000 | 274 |

| 55 | NA4911 | 55 | 63 | 80 | 25 | 1 | 1.5 | 58 | 100 | 4700 | 393 |

| 60 | NA4912 | 60 | 68 | 85 | 25 | 1 | 1.5 | 60 | 108 | 4300 | 426 |

| 65 | NA4913 | 65 | 72 | 90 | 25 | 1 | 1.5 | 61 | 112 | 4100 | 456 |

| 70 | NA4914 | 70 | 80 | 100 | 30 | 1 | 1.5 | 84 | 156 | 3800 | 728 |

| 75 | NA4915 | 75 | 85 | 105 | 30 | 1 | 1.5 | 86 | 162 | 3600 | 775 |

| 80 | NA4916 | 80 | 90 | 110 | 30 | 1 | 1.5 | 89 | 174 | 3400 | 878 |

| 85 | NA4917 | 85 | 100 | 120 | 35 | 1.1 | 1 | 111 | 237 | 2800 | 1250 |

| 90 | NA4918 | 90 | 105 | 125 | 35 | 1.1 | 1 | 114 | 250 | 3000 | 1312 |

| 95 | NA4919 | 95 | 110 | 130 | 3 | 1.1 | 1 | 116 | 260 | 2800 | 1371 |

| 100 | NA4920 | 100 | 115 | 140 | 40 | 1.1 | 2 | 128 | 270 | 2900 | 1900 |

| 110 | NA4922 | 110 | 125 | 150 | 40 | 1.1 | 2 | 132 | 290 | 2600 | 2070 |

| 120 | NA4924 | 120 | 135 | 165 | 45 | 1.1 | 2 | 181 | 390 | 2300 | 2860 |

| 130 | NA4926 | 130 | 150 | 180 | 50 | 1.5 | 1.5 | 203 | 470 | 2000 | 3900 |

| 140 | NA4928 | 140 | 160 | 190 | 50 | 1.5 | 1.5 | 209 | 500 | 1800 | 4150 |

| NO. | NO. | SIZE | ||||

| WITH INNER | WITHOUT INNER | mm | ||||

| d | Fw | D | C | r min | ||

| NA5902 | RNA5902 | 15 | 20 | 28 | 18 | 0.3 |

| NA5903 | RNA5903 | 17 | 22 | 30 | 18 | 0.3 |

| NA5904 | RNA5904 | 20 | 25 | 37 | 23 | 0.3 |

| NA59/22 | RNA59/22 | 22 | 28 | 39 | 23 | 0.3 |

| NA5905 | RNA5905 | 25 | 30 | 42 | 23 | 0.3 |

| NA59/28 | RNA59/28 | 28 | 32 | 45 | 23 | 0.3 |

| NA5906 | RNA5906 | 30 | 35 | 47 | 23 | 0.3 |

| NA59/32 | RNA59/32 | 32 | 40 | 52 | 27 | 0.6 |

| NA5907 | RNA5907 | 35 | 42 | 55 | 27 | 0.6 |

| NA5908 | RNA5908 | 40 | 48 | 62 | 30 | 0.6 |

| NA5909 | RNA5909 | 45 | 52 | 68 | 30 | 0.6 |

| NA5910 | RNA5910 | 50 | 58 | 72 | 30 | 0.6 |

| NA5911 | RNA5911 | 55 | 63 | 80 | 34 | 1 |

| NA5912 | RNA5912 | 60 | 68 | 85 | 34 | 1 |

| NA5913 | RNA5913 | 65 | 72 | 90 | 34 | 1 |

| NA5914 | RNA5914 | 70 | 80 | 100 | 40 | 1 |

| NA5915 | RNA5915 | 75 | 85 | 105 | 40 | 1 |

| NA5916 | RNA5916 | 80 | 90 | 110 | 40 | 1 |

| NA5917 | RNA5917 | 85 | 100 | 120 | 46 | 1.1 |

| NA5918 | RNA5918 | 90 | 105 | 125 | 46 | 1.1 |

| NA5919 | RNA5919 | 95 | 110 | 130 | 46 | 1.1 |

| NA5920 | RNA5920 | 100 | 115 | 140 | 54 | 1.1 |

| NA5922 | RNA5922 | 110 | 125 | 150 | 54 | 1.1 |

| NA5924 | RNA5924 | 120 | 135 | 165 | 60 | 1.1 |

| NA5926 | RNA5926 | 130 | 150 | 180 | 67 | 1.5 |

| NA5928 | RNA5928 | 140 | 160 | 190 | 67 | 1.5 |

| Bearing NO. | Shaft Diameter (mm) | Dimension(mm) | Mass Approx (g) | ||

| Current Code | Fw | D | C | ||

| K3X5X7TN | 3 | 3 | 5 | 7 | 0.3 |

| K3X5X9TN | 3 | 3 | 5 | 9 | 0.4 |

| K3X6X7TN | 3 | 3 | 6 | 7 | 0.4 |

| K4X7X7TN | 4 | 4 | 7 | 7 | 0.5 |

| K4X7X10TN | 4 | 4 | 7 | 10 | 0.7 |

| K5X8X8TN | 5 | 5 | 8 | 8 | 0.7 |

| K5X8X10TN | 5 | 5 | 8 | 10 | 0.9 |

| K6X9X8TN | 6 | 6 | 9 | 8 | 0.8 |

| K6X9X10TN | 6 | 6 | 9 | 10 | 1 |

| K6X10X13TN | 6 | 6 | 10 | 13 | 1.3 |

| K7X10X8TN | 7 | 7 | 10 | 8 | 0.9 |

| K7X10X10TN | 7 | 7 | 10 | 10 | 1.1 |

| K8X11X8TN | 8 | 8 | 11 | 8 | 1.1 |

| K8X11X10TN | 8 | 8 | 11 | 10 | 1.7 |

| K8X11X13TN | 8 | 8 | 11 | 13 | 1.8 |

| K8X12X10TN | 8 | 8 | 12 | 10 | 1.3 |

| K9X12X10TN | 9 | 9 | 12 | 10 | 1.5 |

| K9X12X13TN | 9 | 9 | 12 | 13 | 1.9 |

| K10X13X10TN | 10 | 10 | 13 | 10 | 1.6 |

| K10X13X13TN | 10 | 10 | 13 | 13 | 2.1 |

| K10X13X16TN | 10 | 10 | 13 | 16 | 2.2 |

| K10X14X10TN | 10 | 10 | 14 | 10 | 2.9 |

| K10X14X13TN | 10 | 10 | 14 | 13 | 4.3 |

| K10X16X12TN | 10 | 10 | 16 | 12 | 3.7 |

| K12X15X9TN | 12 | 12 | 15 | 9 | 2.7 |

| K12X15X10TN | 12 | 12 | 15 | 10 | 1.9 |

| K12X15X13TN | 12 | 12 | 15 | 13 | 2.4 |

| K12X16X8TN | 12 | 12 | 16 | 8 | 2.9 |

| K12X16X10TN | 12 | 12 | 16 | 10 | 3.4 |

| K12X16X13TN | 12 | 12 | 16 | 13 | 3.8 |

| K12X17X13TN | 12 | 12 | 17 | 13 | 4.4 |

| K12X18X12TN | 12 | 12 | 18 | 12 | 5 |

| K12X15X20TN | 12 | 12 | 15 | 20 | 3.8 |

| K14X17X10 | 14 | 14 | 17 | 10 | 4 |

| K14X17X17 | 14 | 14 | 17 | 17 | 6.8 |

| K14X18X10 | 14 | 14 | 18 | 10 | 4.8 |

| K14X18X13 | 14 | 14 | 18 | 13 | 6.3 |

| K14X18X14 | 14 | 14 | 18 | 14 | 6.8 |

| K14X18X15 | 14 | 14 | 18 | 15 | 7.3 |

| K14X18X17 | 14 | 14 | 18 | 17 | 8.1 |

| K14X20X12 | 14 | 14 | 20 | 12 | 8.6 |

| K15X18X14 | 15 | 15 | 18 | 14 | 5.3 |

| K15X18X17 | 15 | 15 | 18 | 17 | 6.4 |

| K15X19X10 | 15 | 15 | 19 | 10 | 5.1 |

Why Choose Us:

We are an industrial and trading company.We have our own brand: SFNB .If you interested in our product,I can take you to visit our factory.

Our factory have advanced testing equipment,before the every product leave the factory,we will be testing.We can send samples to you,you can test the quality,and if you accept the sample quality,we can promise: the follow-up orders’ quality will be the same as samples.

About ordinary standard type of bearing ,We have rich inventory,not have MOQ,if your need a product is Non-standard size,need customize,we will according the product size to determine the MOQ.

Our company can accept OEM,you can send sample to me,we can manufacturing products the same as sample.Meanwhile,we also can accept some well-known brands of OEM,

If the amount of money is less,you can pay it by Paypal.Of course you can payment by TT or Western Union etc. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Inner: | 50mm |

|---|---|

| Outer: | 62mm |

| Thickness: | 17mm |

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

How do radial bearings differ from other types of bearings, such as thrust bearings?

Radial bearings and thrust bearings are two distinct types of bearings, each designed to handle different types of loads and forces. Here is a detailed explanation of how radial bearings differ from other types of bearings, particularly thrust bearings:

1. Load Orientation:

The primary difference between radial bearings and thrust bearings lies in the orientation of the loads they can handle. Radial bearings are primarily designed to support radial loads, which are forces that act perpendicular to the shaft’s axis. They are specifically optimized to distribute and support these radial loads, such as the weight of rotating shafts or components, belt tension, or pulley forces.

On the other hand, thrust bearings are designed to handle axial (thrust) loads, which are forces that act parallel to the shaft’s axis. These loads can include pushing or pulling forces, as well as the weight of components or structures that exert an axial force. Thrust bearings are specifically engineered to accommodate and transmit these axial loads while minimizing friction and ensuring smooth operation.

2. Bearing Design:

Radial bearings and thrust bearings have different design features to suit their respective load orientations. Radial bearings typically have an inner ring mounted on the rotating shaft and an outer ring that remains stationary. The rolling elements, such as balls or rollers, are positioned between the inner and outer rings and distribute the radial load. The design of radial bearings focuses on providing optimal support and distributing the load evenly across the rolling elements.

Thrust bearings, on the other hand, have different design configurations to handle axial loads. They can be categorized into several types, including ball thrust bearings, roller thrust bearings, tapered roller thrust bearings, and spherical roller thrust bearings. These designs often incorporate specialized features such as raceway profiles, cage structures, and rolling element arrangements to handle axial loads while minimizing friction and accommodating misalignments.

3. Load Capacity and Direction:

Radial bearings and thrust bearings have different load capacities and capabilities in terms of load direction. Radial bearings are optimized to handle primarily radial loads, and their load capacity is typically specified for radial forces. While they can withstand limited axial loads, their axial load capacity is lower compared to dedicated thrust bearings. Radial bearings are not designed to handle significant axial forces and may experience premature wear or failure if subjected to excessive axial loads.

Thrust bearings, on the other hand, are specifically engineered to handle axial loads. They have higher axial load capacities compared to radial bearings and are designed to transmit and support forces acting parallel to the shaft’s axis. Thrust bearings are capable of withstanding substantial axial loads without sacrificing their performance or longevity.

4. Application and Usage:

Due to their load orientation and design characteristics, radial bearings and thrust bearings are used in different applications. Radial bearings are commonly employed in machinery and equipment where supporting radial loads is the primary requirement. They are widely used in applications such as electric motors, pumps, fans, conveyors, automotive components, and industrial machinery. Radial bearings are versatile and can handle various operating conditions, speeds, and loads, making them suitable for a wide range of mechanical systems.

Thrust bearings, on the other hand, are specifically used in applications where axial loads need to be supported and transmitted. They find application in machinery and equipment such as thrust ball screws, automotive transmissions, steering systems, and heavy machinery that requires precise axial positioning. Thrust bearings are crucial for maintaining the axial integrity and stability of components or structures subjected to thrust forces.

5. Combination Bearings:

In some cases, there are bearings that can handle both radial and axial loads, commonly known as combination bearings or angular contact bearings. These bearings are designed with a specific contact angle between the rolling elements and raceways, allowing them to simultaneously support radial and axial loads. Combination bearings are often used in applications where both types of loads are present, such as machine tool spindles or certain types of gearboxes. However, it’s important to note that combination bearings may have limitations in terms of load capacities and the ratio of radial to axial loads they can handle.

In summary, the primary differences between radial bearings and other types of bearings, such as thrust bearings, lie in their load orientations, design features, load capacities, and applications. Radial bearings are optimized for supporting radial loads, while thrust bearings are specifically designed to handle axial loads. Understanding these differences is crucial for selecting the appropriate bearing type for a specific mechanical application.

How do radial bearings perform in high-speed or high-load applications?

Radial bearings are designed to perform reliably in high-speed or high-load applications, where they are subjected to demanding operating conditions. These bearings are engineered to withstand the forces and speeds associated with such applications. Here’s a detailed explanation of how radial bearings perform in high-speed or high-load applications:

1. High-Speed Applications:

In high-speed applications, radial bearings are designed to minimize friction and reduce heat generation. They employ various features to achieve this, such as optimized ball or roller designs, precise manufacturing tolerances, and advanced cage materials. These design elements help reduce centrifugal forces, improve rolling element guidance, and maintain stable operation at high rotational speeds. Additionally, high-quality lubricants are used to ensure proper lubrication and temperature control, enabling the bearing to operate efficiently and reliably even at high speeds.

2. High-Load Applications:

Radial bearings are engineered to handle high loads encountered in various applications. They are designed with robust construction, using high-quality materials and advanced bearing geometries. These features enable radial bearings to distribute the applied loads evenly across their contact surfaces, minimizing stress concentrations and preventing premature failure. Additionally, radial bearings may incorporate specialized cage designs or additional rollers or balls to enhance their load-carrying capacity. The selection of the appropriate bearing type and size, along with proper lubrication, is crucial to ensure optimal performance and longevity in high-load applications.

3. Heat Dissipation:

In both high-speed and high-load applications, radial bearings must effectively dissipate heat generated during operation. Excessive heat can lead to premature bearing failure or degradation of lubricants. Radial bearings are designed with features that promote efficient heat dissipation, such as internal clearances, optimized bearing materials, and effective lubrication systems. These features help maintain the operating temperature within acceptable limits, ensuring the integrity and performance of the bearing in demanding conditions.

4. Cage Design:

The cage design of radial bearings is an essential factor in their performance in high-speed or high-load applications. The cage holds the rolling elements in position, preventing contact and ensuring proper spacing. In high-speed applications, cages with low friction and good guidance properties are used to minimize heat generation and maintain stable operation. In high-load applications, stronger and stiffer cage materials are employed to withstand the forces exerted by the applied loads. The cage design is optimized to balance the trade-off between strength, guidance, and friction characteristics, ensuring the reliable performance of the radial bearing under demanding conditions.

5. Lubrication and Contamination Control:

In high-speed or high-load applications, proper lubrication is crucial for the performance and longevity of radial bearings. Lubricants with high viscosity and excellent thermal stability are used to ensure adequate lubrication under extreme conditions. Effective lubrication minimizes friction, reduces wear, and controls temperature rise. Additionally, contamination control is essential to prevent abrasive particles or contaminants from entering the bearing and causing damage. Sealing solutions and proper maintenance practices are employed to safeguard the bearing against contamination in high-speed or high-load applications.

6. Application-Specific Considerations:

When using radial bearings in high-speed or high-load applications, it is important to consider the specific requirements and conditions of the application. Factors such as operating temperature, rotational speed, applied loads, vibration levels, and environmental conditions should be taken into account during the bearing selection process. Working closely with bearing manufacturers or industry experts can help ensure that the chosen radial bearings are suitable for the specific high-speed or high-load application, optimizing performance and maximizing bearing life.

In summary, radial bearings are designed to perform reliably in high-speed or high-load applications. Through their specialized design, robust construction, efficient heat dissipation, optimized cage designs, proper lubrication, and consideration of application-specific factors, radial bearings can meet the challenges of demanding operating conditions, providing reliable and long-lasting performance.

How do innovations and advancements in radial bearing technology impact their use?

Innovations and advancements in radial bearing technology have a significant impact on their use in various industries and applications. These advancements drive improvements in performance, reliability, efficiency, and versatility of radial bearings. Here’s a detailed explanation of how innovations and advancements in radial bearing technology impact their use:

1. Enhanced Performance:

Advancements in radial bearing technology lead to improved performance characteristics. This includes increased load capacities, higher rotational speeds, reduced friction, and enhanced stiffness. These improvements allow radial bearings to handle more demanding loads and operate in high-speed applications more effectively. Enhanced performance enables the use of radial bearings in a wider range of industrial applications, contributing to increased efficiency and productivity.

2. Extended Service Life:

Innovations in bearing materials, lubrication systems, and surface treatments result in extended service life for radial bearings. New materials with superior wear resistance and corrosion resistance properties allow bearings to withstand harsh environments and reduce the risk of premature failure. Advanced lubrication techniques, such as self-lubricating or solid lubricant coatings, minimize friction and wear, further prolonging the bearing’s service life. The ability of radial bearings to operate reliably for longer periods translates into reduced maintenance requirements and downtime.

3. Improved Reliability:

Advancements in radial bearing technology enhance their overall reliability. New designs and manufacturing techniques ensure consistent quality, dimensional accuracy, and precise tolerances, resulting in reliable performance under varying operating conditions. The use of advanced simulation and testing methods enables better prediction and understanding of bearing behavior, allowing for optimized designs and improved reliability. Enhanced reliability reduces the risk of unexpected bearing failures, which can lead to costly downtime and equipment damage.

4. Higher Efficiency:

Innovations in radial bearing technology contribute to higher efficiency in mechanical systems. Reduced friction and improved lubrication techniques minimize energy losses within the bearing, resulting in improved overall system efficiency. Bearings with lower friction help reduce power consumption and improve energy utilization, making them particularly beneficial in applications where energy efficiency is a priority, such as electric motors or automotive drivetrains.

5. Miniaturization and Compact Designs:

Advancements in radial bearing technology enable the development of smaller and more compact bearing designs. This is particularly important in industries where space constraints are a significant consideration. Miniaturized bearings allow for the design of smaller and lighter equipment without compromising performance. They find applications in industries such as aerospace, robotics, medical devices, and electronics, where size and weight reduction are crucial.

6. Specialized Applications:

Innovations in radial bearing technology have led to the development of specialized bearings tailored for specific applications. For example, advancements in bearing materials and designs have resulted in bearings capable of operating in extreme temperature or high-vibration environments. Specialized bearings designed for specific industries, such as the food and beverage or pharmaceutical sectors, meet stringent regulatory requirements regarding hygiene and contamination prevention. These specialized bearings expand the range of applications where radial bearings can be used effectively.

7. Integration with Sensor Technologies:

Advancements in sensor technologies have facilitated the integration of condition monitoring and predictive maintenance capabilities into radial bearings. Bearings equipped with sensors can provide real-time data on factors such as temperature, vibration, and load conditions. This allows for proactive maintenance and early detection of potential issues, enabling timely interventions to prevent unplanned downtime and optimize equipment performance.

8. Cost Optimization:

While innovations and advancements in radial bearing technology often involve initial investments in research and development, they can lead to long-term cost savings. Improved performance, extended service life, and reduced maintenance requirements result in lower operational costs over the bearing’s lifetime. Additionally, advancements in manufacturing processes and economies of scale may contribute to more affordable bearing options, making advanced radial bearing technology accessible to a wider range of applications.

By continually pushing the boundaries of radial bearing technology, innovations and advancements have a profound impact on their use across various industries. Enhanced performance, extended service life, improved reliability, higher efficiency, miniaturization, specialized applications, integration with sensor technologies, and cost optimization are some of the key benefits that result from these advancements. As a result, engineers and designers have access to a wider range of bearing options to meet the evolving needs of modern industrial applications.

editor by CX 2024-04-23