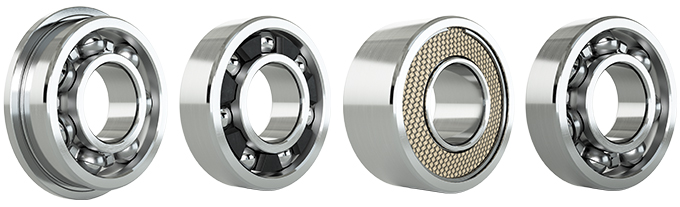

Product Description

I have all the models you need, these are just some of them, please contact us now

-

UC Series – Standard duty, setscrew locking type with wide inner ring bearing. Triple lip seals (R3 suffix) optional.

-

HC Series – Standard duty, Eccentric locking collar type with wide inner ring bearing. Triple lip seals (R3 suffix) optional.

-

UCX Series – Medium duty, setscrew locking type with wide inner ring bearing.

-

SA..G Series – Light duty, Eccentric locking collar type with narrow inner ring bearing. SA has spherical OD; CSAhas cylindrical OD. Also available with full contact rubber seal (2RS suffix) and non-relubricatable units (remove G suffix).

-

CSASeries – Light duty narrow inner ring bearing with a cylindrical OD, full cover metal slinger seals, Eccentric collar locking, and non-relubricable.

-

SB..G Series – Light duty narrow inner ring bearing with a spherical OD, full cover metal slinger seals, set screw locking, and re-lubrication groove with oil hole on set screw side. Available non-relubricable (remove the G suffix).

-

CSB Series – Light duty narrow inner ring bearing with a cylindrical OD, full cover metal slinger seals, set screw locking, and non-relubricable.

-

SER Series – Standard duty, setscrew locking type with cylindrical OD and wide inner ring bearing and snap ring on setscrew side.

Pillow Block Bearings Widely used in various industries, our bearings meet the requirements of your project!

1.FREE SAMPLES:

contact us by email or trade manager, we will send the free sampls according to your request.

2. World Class Bearing:We provide our customers with all type of indigenous bearing with world class quality.

3. OEM or Non Stand Bearings: Any requirement for Non standard bearings is Easily Fulfilled by us due to

its vast knowledge and links in the industry.

4. Genuine products With Excellent Quality: Company has always proved the

100% quality products it provides with genuine intent.

5.After Sales Service and technical Assistance: Company provides after sales service and technical assistance

as per the customers requirement and needs.

6. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

7. Cost Saving: We provide long-life, shock-resistant and high reliability bearings with

excellent quality and better performance. Resulting in increased cost saving.

8.Attending customer queries promptly: We believe that if customer are satisfied then it proves our worth well. Customers are always given quick support.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| OEM: | Available |

|---|---|

| Precision Rating: | P0, P6, P5 |

| Transportation: | by Air or by Sea |

| Seals Type: | Zz |

| Bore Size: | 10-100mm |

| Type: | 6000zz |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the primary functions of radial bearings in machinery and equipment?

Radial bearings play several primary functions in machinery and equipment. They are essential components that provide support, facilitate smooth rotation, and minimize friction in various mechanical systems. Here is a detailed explanation of the primary functions of radial bearings:

1. Load Support:

The primary function of radial bearings is to support loads in machinery and equipment. Radial bearings are designed to withstand radial loads, which are forces that act perpendicular to the shaft’s axis. These loads can include the weight of rotating shafts, belts, pulleys, or other components that exert a radial force. Radial bearings distribute the load evenly across the rolling elements and transmit it to the stationary outer ring. By supporting and distributing the load, radial bearings prevent excessive stress on the rotating components and ensure smooth operation.

2. Facilitating Smooth Rotation:

Radial bearings are crucial for facilitating smooth rotation in machinery and equipment. The rolling elements, such as balls or rollers, in a radial bearing roll between the inner and outer rings. This rolling action reduces friction and enables smooth motion of the rotating shaft or assembly. The low friction provided by radial bearings minimizes energy loss and allows machinery to operate efficiently. By enabling smooth rotation, radial bearings contribute to the overall performance and functionality of the machinery or equipment.

3. Reducing Friction and Power Loss:

Friction is an inherent challenge in mechanical systems that can lead to power loss, heat generation, and premature wear. Radial bearings are designed to minimize friction between the rolling elements and raceways. The rolling motion of the elements reduces sliding friction, resulting in lower power loss and improved energy efficiency. By reducing friction, radial bearings help optimize the performance of machinery and equipment, allowing them to operate with increased reliability and efficiency.

4. Absorbing and Damping Vibrations:

Machinery and equipment can experience vibrations due to various factors, such as imbalances, misalignments, or external forces. Radial bearings play a role in absorbing and damping vibrations within the system. The rolling elements and the bearing structure act as a buffer, absorbing and dissipating vibrations generated during operation. By absorbing vibrations, radial bearings reduce the impact on other components, minimize the risk of damage or excessive wear, and contribute to a smoother and quieter operation of the machinery.

5. Supporting Axial Loads (Limited):

Although radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as thrust or pushing forces. While radial bearings are not specifically optimized for axial loads like dedicated thrust bearings, they can handle moderate axial loads that may be present in certain applications. However, it is important to consider the axial load capacity of the specific radial bearing and ensure that the applied axial load remains within its limits.

6. Enabling Compact and Space-Efficient Designs:

Radial bearings offer the advantage of enabling compact and space-efficient designs in machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions and tighter tolerances. By using radial bearings, machinery and equipment can be more compact, lightweight, and efficient without compromising their performance or load-carrying capabilities. This space-saving feature is particularly valuable in applications where space constraints or weight considerations are critical factors.

7. Providing Mechanical Stability:

Radial bearings contribute to the mechanical stability of machinery and equipment. They help maintain the proper alignment of rotating components, preventing excessive vibration, misalignment, or skewing. The precise fit and alignment of the bearing components ensure that the rotating shaft or assembly operates within the desired tolerances. This mechanical stability provided by radial bearings is crucial for the overall performance, reliability, and longevity of the machinery or equipment.

In summary, the primary functions of radial bearings in machinery and equipment include load support, facilitating smooth rotation, reducing friction and power loss, absorbing and damping vibrations, supporting limited axial loads, enabling compact designs, and providing mechanical stability. Radial bearings play a critical role in optimizing the performance, reliability, and efficiency of various mechanical systems.

Can radial bearings be customized or modified for unique industrial needs?

Radial bearings can indeed be customized or modified to meet unique industrial needs. Manufacturers often offer customization options to provide bearings that are tailored to specific application requirements. Customization allows for the optimization of various aspects of the bearing, such as size, design, materials, lubrication, and sealing, among others. Here’s a detailed explanation of the customization and modification possibilities for radial bearings:

1. Size and Design:

Radial bearings can be customized in terms of size and design to fit specific space constraints or load requirements. Manufacturers can adjust the dimensions of the bearing, such as the bore diameter, outer diameter, or width, to match the application’s unique specifications. Additionally, the bearing design can be modified to accommodate specific performance needs, such as increased load capacity, enhanced stiffness, or improved rotational speed capabilities.

2. Materials:

The choice of materials used in radial bearings can be customized based on the application’s needs. Different materials offer varying levels of strength, corrosion resistance, temperature resistance, and other properties. For example, in high-temperature environments, bearings can be customized with heat-resistant materials, such as ceramic or high-temperature alloys, to ensure reliable operation. Similarly, for applications where corrosion is a concern, bearings can be customized with corrosion-resistant coatings or materials.

3. Lubrication:

Radial bearings can be customized in terms of lubrication requirements. The lubrication type and quantity can be modified to suit specific operating conditions. For instance, bearings operating in high-speed applications may require specialized lubricants that can withstand high temperatures and provide sufficient lubrication film thickness. Customized lubrication solutions can help optimize bearing performance, reduce friction, and extend the bearing’s service life.

4. Sealing and Protection:

Bearing customization can include modifications to the sealing and protection features. Seals or shields can be customized to provide enhanced protection against contaminants, moisture, or other environmental factors. By choosing the appropriate sealing solution, the ingress of dust, dirt, or liquids can be minimized, improving the bearing’s reliability and longevity. Customized sealing options can also help reduce maintenance requirements and prevent premature failure.

5. Specialized Coatings:

In certain industrial applications, specialized coatings can be applied to radial bearings to enhance their performance. These coatings can provide benefits such as increased wear resistance, reduced friction, improved corrosion resistance, or enhanced operating characteristics under specific conditions. Customized coatings can be designed based on the specific application needs, ensuring optimal performance and longevity of the bearings in demanding environments.

6. Mounting and Fit:

Customization of radial bearings can include modifications to the mounting and fit requirements. For unique applications where standard mounting methods are not suitable, manufacturers can customize the bearing’s mounting features to ensure proper fit and alignment within the system. This may involve modifications to the bearing’s outer ring, inner ring, or flange design to accommodate specific mounting arrangements or requirements.

7. Application-Specific Considerations:

Manufacturers of radial bearings are often willing to work closely with customers to understand their unique industrial needs and develop customized solutions. By considering application-specific factors such as load conditions, operating environment, speed requirements, and space limitations, manufacturers can tailor the design and specifications of radial bearings to provide optimal performance and reliability.

It is important to note that customization of radial bearings may involve additional costs and lead time compared to off-the-shelf bearings. However, the benefits of having bearings specifically tailored to the application’s requirements often outweigh these considerations, as they can result in improved performance, increased service life, and reduced downtime.

Overall, radial bearings can be customized or modified to meet unique industrial needs, allowing for the optimization of various parameters to ensure optimal performance, reliability, and longevity in specific applications. Collaborating with bearing manufacturers or industry experts can help identify the customization possibilities and develop tailored solutions that address the specific requirements of the industrial application.

Are there specific considerations for choosing radial bearings in applications with varying radial loads or operating conditions?

Choosing radial bearings for applications with varying radial loads or operating conditions requires careful consideration of several factors. The selection process should take into account the specific requirements and challenges posed by the varying loads and operating conditions. Here’s a detailed explanation of the specific considerations for choosing radial bearings in such applications:

1. Load Capacity:

One of the primary considerations is the load capacity of the radial bearing. It is essential to evaluate the expected range of radial loads and ensure that the selected bearing can handle the maximum load without exceeding its capacity. The load capacity of a bearing is typically specified by the manufacturer and is influenced by factors such as bearing size, design, and materials. It is important to choose a bearing with a sufficient load capacity to accommodate the varying radial loads encountered in the application.

2. Dynamic and Static Load Ratings:

The dynamic and static load ratings provided by the bearing manufacturer are crucial for assessing the bearing’s ability to handle varying loads. The dynamic load rating indicates the maximum load a bearing can sustain for a specified number of rotations without experiencing excessive wear or fatigue. The static load rating represents the maximum load the bearing can withstand without permanent deformation. Comparing the expected loads in the application with the dynamic and static load ratings helps ensure that the selected bearing is suitable for the varying radial loads.

3. Bearing Clearance:

Bearing clearance refers to the internal gap between the rolling elements and the raceways. In applications with varying loads, it is important to consider the appropriate bearing clearance. A tighter clearance may be suitable for higher loads as it minimizes internal movement and reduces the risk of excessive wear. On the other hand, a looser clearance may be preferred for lighter loads to ensure smooth operation and minimize friction. It is crucial to consult the bearing manufacturer’s guidelines and recommendations to determine the optimal clearance for the specific application.

4. Lubrication:

Varying radial loads can affect the lubrication requirements of the bearing. Higher loads may result in increased friction and heat generation, necessitating appropriate lubrication to ensure proper operation and prevent premature failure. It is important to select the right type of lubricant and consider factors such as viscosity, temperature range, and compatibility with the bearing materials. In applications with varying loads, periodic monitoring of lubrication conditions and maintenance intervals is essential to ensure optimal lubrication and prevent issues associated with inadequate lubrication.

5. Bearing Design and Materials:

The design and materials of the radial bearing play a significant role in its ability to withstand varying loads and operating conditions. Different bearing designs, such as deep groove ball bearings, cylindrical roller bearings, or tapered roller bearings, have varying load capacities and performance characteristics. The choice of bearing material, such as steel, ceramic, or polymer, can also impact factors such as strength, fatigue resistance, and corrosion resistance. It is important to select a bearing design and material that are suitable for the anticipated loads and operating conditions in the application.

6. Temperature and Environmental Factors:

Varying radial loads can affect the temperature and environmental conditions within the bearing. Higher loads can result in increased heat generation, which may require additional considerations for heat dissipation and thermal management. Similarly, if the application involves exposure to moisture, chemicals, or abrasive particles, it is important to select a bearing with appropriate seals or shields to protect against contamination. Considering the temperature and environmental factors helps ensure the longevity and reliability of the bearing in applications with varying loads.

7. Application-Specific Considerations:

Each application may have unique requirements or constraints that need to be taken into account when selecting radial bearings. Factors such as speed, vibration levels, mounting arrangements, space limitations, and maintenance accessibility should be considered. Consulting with bearing manufacturers or industry experts can provide valuable insights and guidance for choosing the most suitable radial bearings for applications with varying loads and operating conditions.

By carefully evaluating these specific considerations, it is possible to select radial bearings that can reliably and efficiently handle the varying radial loads encountered in the application, ensuring optimal performance and durability.

editor by CX 2024-03-23