Product Description

Overview

Quick Details

Type:Roller

Structure:Taper

Applicable Industries:Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company, Mechanical industry

Brand Name:TFN

Model Number:28985/20

Precision Rating:P0 P6 P5 P4 P2

Seals Type:No seal

Number of Row:Single Row

Place of Origin:ZheJiang , China

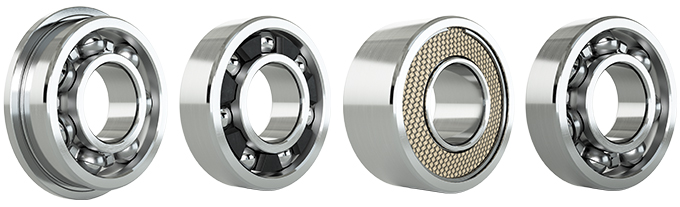

Product name:Gearbox Chrome Steel Auto Wheel Radial Inch Tapered Roller Bearing

Material:Chromel steel (Gcr15)

Cage:Steel

Weight:0.81 kg

Dimension:60.325×1 bearing?

A: CZPT Bearing MOQ is 1 pc.

5.Q:What kind of service you can offer?

A:Technology support;Installation guidance;OEM. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Chrome Steel Gcr15 |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Axial Bearing |

| Samples: |

US$ 5.4/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can you explain the primary functions of radial bearings in machinery and equipment?

Radial bearings play several primary functions in machinery and equipment. They are essential components that provide support, facilitate smooth rotation, and minimize friction in various mechanical systems. Here is a detailed explanation of the primary functions of radial bearings:

1. Load Support:

The primary function of radial bearings is to support loads in machinery and equipment. Radial bearings are designed to withstand radial loads, which are forces that act perpendicular to the shaft’s axis. These loads can include the weight of rotating shafts, belts, pulleys, or other components that exert a radial force. Radial bearings distribute the load evenly across the rolling elements and transmit it to the stationary outer ring. By supporting and distributing the load, radial bearings prevent excessive stress on the rotating components and ensure smooth operation.

2. Facilitating Smooth Rotation:

Radial bearings are crucial for facilitating smooth rotation in machinery and equipment. The rolling elements, such as balls or rollers, in a radial bearing roll between the inner and outer rings. This rolling action reduces friction and enables smooth motion of the rotating shaft or assembly. The low friction provided by radial bearings minimizes energy loss and allows machinery to operate efficiently. By enabling smooth rotation, radial bearings contribute to the overall performance and functionality of the machinery or equipment.

3. Reducing Friction and Power Loss:

Friction is an inherent challenge in mechanical systems that can lead to power loss, heat generation, and premature wear. Radial bearings are designed to minimize friction between the rolling elements and raceways. The rolling motion of the elements reduces sliding friction, resulting in lower power loss and improved energy efficiency. By reducing friction, radial bearings help optimize the performance of machinery and equipment, allowing them to operate with increased reliability and efficiency.

4. Absorbing and Damping Vibrations:

Machinery and equipment can experience vibrations due to various factors, such as imbalances, misalignments, or external forces. Radial bearings play a role in absorbing and damping vibrations within the system. The rolling elements and the bearing structure act as a buffer, absorbing and dissipating vibrations generated during operation. By absorbing vibrations, radial bearings reduce the impact on other components, minimize the risk of damage or excessive wear, and contribute to a smoother and quieter operation of the machinery.

5. Supporting Axial Loads (Limited):

Although radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as thrust or pushing forces. While radial bearings are not specifically optimized for axial loads like dedicated thrust bearings, they can handle moderate axial loads that may be present in certain applications. However, it is important to consider the axial load capacity of the specific radial bearing and ensure that the applied axial load remains within its limits.

6. Enabling Compact and Space-Efficient Designs:

Radial bearings offer the advantage of enabling compact and space-efficient designs in machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions and tighter tolerances. By using radial bearings, machinery and equipment can be more compact, lightweight, and efficient without compromising their performance or load-carrying capabilities. This space-saving feature is particularly valuable in applications where space constraints or weight considerations are critical factors.

7. Providing Mechanical Stability:

Radial bearings contribute to the mechanical stability of machinery and equipment. They help maintain the proper alignment of rotating components, preventing excessive vibration, misalignment, or skewing. The precise fit and alignment of the bearing components ensure that the rotating shaft or assembly operates within the desired tolerances. This mechanical stability provided by radial bearings is crucial for the overall performance, reliability, and longevity of the machinery or equipment.

In summary, the primary functions of radial bearings in machinery and equipment include load support, facilitating smooth rotation, reducing friction and power loss, absorbing and damping vibrations, supporting limited axial loads, enabling compact designs, and providing mechanical stability. Radial bearings play a critical role in optimizing the performance, reliability, and efficiency of various mechanical systems.

How do radial bearings perform in high-speed or high-load applications?

Radial bearings are designed to perform reliably in high-speed or high-load applications, where they are subjected to demanding operating conditions. These bearings are engineered to withstand the forces and speeds associated with such applications. Here’s a detailed explanation of how radial bearings perform in high-speed or high-load applications:

1. High-Speed Applications:

In high-speed applications, radial bearings are designed to minimize friction and reduce heat generation. They employ various features to achieve this, such as optimized ball or roller designs, precise manufacturing tolerances, and advanced cage materials. These design elements help reduce centrifugal forces, improve rolling element guidance, and maintain stable operation at high rotational speeds. Additionally, high-quality lubricants are used to ensure proper lubrication and temperature control, enabling the bearing to operate efficiently and reliably even at high speeds.

2. High-Load Applications:

Radial bearings are engineered to handle high loads encountered in various applications. They are designed with robust construction, using high-quality materials and advanced bearing geometries. These features enable radial bearings to distribute the applied loads evenly across their contact surfaces, minimizing stress concentrations and preventing premature failure. Additionally, radial bearings may incorporate specialized cage designs or additional rollers or balls to enhance their load-carrying capacity. The selection of the appropriate bearing type and size, along with proper lubrication, is crucial to ensure optimal performance and longevity in high-load applications.

3. Heat Dissipation:

In both high-speed and high-load applications, radial bearings must effectively dissipate heat generated during operation. Excessive heat can lead to premature bearing failure or degradation of lubricants. Radial bearings are designed with features that promote efficient heat dissipation, such as internal clearances, optimized bearing materials, and effective lubrication systems. These features help maintain the operating temperature within acceptable limits, ensuring the integrity and performance of the bearing in demanding conditions.

4. Cage Design:

The cage design of radial bearings is an essential factor in their performance in high-speed or high-load applications. The cage holds the rolling elements in position, preventing contact and ensuring proper spacing. In high-speed applications, cages with low friction and good guidance properties are used to minimize heat generation and maintain stable operation. In high-load applications, stronger and stiffer cage materials are employed to withstand the forces exerted by the applied loads. The cage design is optimized to balance the trade-off between strength, guidance, and friction characteristics, ensuring the reliable performance of the radial bearing under demanding conditions.

5. Lubrication and Contamination Control:

In high-speed or high-load applications, proper lubrication is crucial for the performance and longevity of radial bearings. Lubricants with high viscosity and excellent thermal stability are used to ensure adequate lubrication under extreme conditions. Effective lubrication minimizes friction, reduces wear, and controls temperature rise. Additionally, contamination control is essential to prevent abrasive particles or contaminants from entering the bearing and causing damage. Sealing solutions and proper maintenance practices are employed to safeguard the bearing against contamination in high-speed or high-load applications.

6. Application-Specific Considerations:

When using radial bearings in high-speed or high-load applications, it is important to consider the specific requirements and conditions of the application. Factors such as operating temperature, rotational speed, applied loads, vibration levels, and environmental conditions should be taken into account during the bearing selection process. Working closely with bearing manufacturers or industry experts can help ensure that the chosen radial bearings are suitable for the specific high-speed or high-load application, optimizing performance and maximizing bearing life.

In summary, radial bearings are designed to perform reliably in high-speed or high-load applications. Through their specialized design, robust construction, efficient heat dissipation, optimized cage designs, proper lubrication, and consideration of application-specific factors, radial bearings can meet the challenges of demanding operating conditions, providing reliable and long-lasting performance.

How do radial bearings enhance the overall efficiency and functionality of machinery and equipment?

Radial bearings play a critical role in enhancing the overall efficiency and functionality of machinery and equipment. They enable smooth and reliable rotational motion, reduce friction, support heavy loads, and provide stability. Here’s a detailed explanation of how radial bearings contribute to the efficiency and functionality of machinery and equipment:

1. Reduced Friction:

Radial bearings are designed to minimize friction between moving parts. By providing a smooth interface between rotating components, they reduce energy losses due to friction. This results in improved energy efficiency and reduced power consumption. Bearings with low friction characteristics help optimize the performance of machinery by minimizing heat generation, reducing wear, and preventing premature failure of components.

2. Load Support:

Radial bearings are specifically designed to support radial loads, which are forces acting perpendicular to the rotation axis. They distribute the applied loads evenly across the bearing surfaces, preventing excessive stress on individual components. By efficiently supporting loads, radial bearings help maintain the structural integrity of machinery and equipment, ensuring smooth operation and preventing component failures.

3. Shaft Alignment and Stability:

Radial bearings contribute to the alignment and stability of rotating shafts. They help maintain accurate positioning of the shafts, ensuring proper alignment with other components. This alignment minimizes vibrations, reduces noise, and avoids unnecessary wear and tear. By providing stability, radial bearings enable machinery to operate smoothly and with precision, enhancing overall functionality.

4. Increased Rotational Speed:

Radial bearings are designed to accommodate high rotational speeds. They provide smooth rolling or sliding motion, minimizing the centrifugal forces generated at high speeds. By allowing machinery and equipment to operate at higher speeds, radial bearings enhance productivity and throughput. Increased rotational speed can lead to shorter processing times, higher production rates, and improved overall efficiency.

5. Noise and Vibration Reduction:

Properly selected and maintained radial bearings help reduce noise and vibration in machinery and equipment. They act as dampers, absorbing and dissipating vibrations generated by rotating components. By minimizing vibrations, radial bearings contribute to a quieter operating environment, improve operator comfort, and reduce the risk of damage to sensitive components.

6. Compact Design and Space Optimization:

Radial bearings are available in various sizes and configurations, allowing for compact design and space optimization in machinery and equipment. Their small footprint and high load-carrying capacity make them ideal for applications with limited space. By enabling compact designs, radial bearings facilitate the integration of additional components, reduce the overall size of the equipment, and increase efficiency in terms of space utilization.

7. Maintenance and Reliability:

Radial bearings require regular maintenance to ensure optimal performance and reliability. However, compared to other components in machinery and equipment, bearings are relatively easy to maintain. Proper lubrication, monitoring of operating conditions, and periodic inspection can help prevent premature failure and extend the service life of bearings. By reducing downtime and the need for frequent repairs, radial bearings enhance the overall efficiency and functionality of machinery.

8. Application Versatility:

Radial bearings are available in a wide range of types, sizes, and materials, making them versatile for various applications. Different bearing configurations and materials can be selected based on specific operational requirements, load conditions, and environmental factors. This versatility allows engineers to optimize the performance and efficiency of machinery and equipment for specific applications, ensuring reliable operation and maximizing productivity.

Overall, radial bearings are essential components that significantly enhance the efficiency and functionality of machinery and equipment. By reducing friction, supporting loads, providing stability, accommodating high speeds, minimizing noise and vibration, enabling compact designs, facilitating maintenance, and offering application versatility, radial bearings contribute to the smooth operation, improved performance, and extended service life of machinery and equipment in various industries.

editor by CX 2024-04-04