Product Description

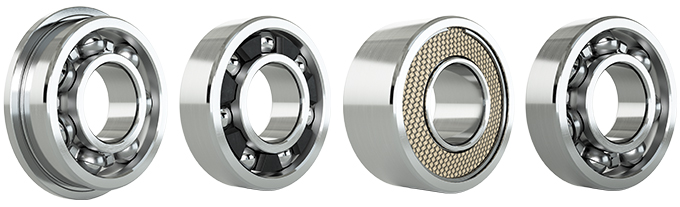

High Precision NCF2940V SL182940 Cylindrical Roller Radial Bearings

|

Product Name |

High Precision NCF2940V SL182940 Cylindrical Roller Radial Bearings |

|

Brand |

TFN / OEM |

|

Model Number |

NCF2940V SL182940 |

|

Ring Material |

Steel |

|

Cage Material |

Brass,Nylon,Steel |

|

Precision |

P0, P6, P5, or as requested |

|

Vibration |

ZV1, ZV2, ZV3, or as requested |

|

Clearance |

C0,C2,C3, or as requested |

|

Type |

SL series ,N series,NU series,NJ series,Nup series,NF series |

|

Features |

High load carrying capacity ,High stiffness,Accommodate axial displacement ,Low friction ,Long service life,Enhanced operational reliability ,Separable and interchangeable . |

|

Quality standard |

ISO9001:2000/ SGS |

|

Quality Control Process |

1.Assembly |

|

2.Windage test |

|

|

3.Cleaning |

|

|

4.Rotary test |

|

|

5.Greasing and gland |

|

|

6.Noise inspection |

|

|

7.Appearance inspection |

|

|

8.Rust prevention |

|

|

9.Product packaging |

|

|

Application |

cylindrical roller bearing is usually only subject to radial force. Compared with ball bearing of the same size, its radial bearing capacity is increased by 1.5-3 times. It is rigid and shock resistant. It is mainly used for large motor, machine tool spindle, engine front and rear support shaft, train bus axle, diesel engine crankshaft, automobile tractor gearbox, etc. |

Other cylindrical roller bearing models :

| Designation | Principal dimensions | Basic load ratings | Fatigue load limit | Speed ratings | ||||

| dynamic | static | Reference speed | Limiting speed | |||||

| d | D | B | C | C0 | Pu | |||

| mm | kN | kN | r/min | |||||

| NU 202 ECP | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 26000 |

| NU 202 ECPHA | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 34000 |

| NJ 202 ECP | 15 | 35 | 11 | 12.5 | 10.2 | 1.22 | 22000 | 26000 |

| NU 203 ECML | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 34000 |

| NJ 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| N 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NJ 203 ECPHA | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 30000 |

| NU 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NUP 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| NU 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| NUP 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 203 ECML | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 34000 |

| N 203 ECP | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NU 2203 ECP | 17 | 40 | 16 | 27.5 | 21.6 | 2.65 | 20000 | 22000 |

| N 203 ECPH | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 22000 |

| NJ 303 ECP | 17 | 47 | 14 | 28.5 | 20.4 | 2.55 | 17000 | 20000 |

| NU 203 ECPHA | 17 | 40 | 12 | 20 | 14.3 | 1.73 | 20000 | 30000 |

| NU 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| N 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NU 2204 ECP | 20 | 47 | 18 | 34.5 | 27.5 | 3.45 | 17000 | 19000 |

| NUP 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NUP 204 ECPHA | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 24000 |

| NJ 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| NU 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

| NUP 2304 ECP | 20 | 52 | 21 | 47.5 | 38 | 4.8 | 15000 | 18000 |

| NU 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 204 ECPHA | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 24000 |

| NU 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NJ 2204 ECP | 20 | 47 | 18 | 34.5 | 27.5 | 3.45 | 17000 | 19000 |

| NUP 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NUP 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

| N 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 204 ECP | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 19000 |

| NJ 304 ECP | 20 | 52 | 15 | 35.5 | 26 | 3.25 | 15000 | 18000 |

| NJ 204 ECML | 20 | 47 | 14 | 28.5 | 22 | 2.75 | 17000 | 30000 |

Certificate

Packing

FAQ

Q:Why choose SEMRI?

A:1. We are professional,have factory in ZheJiang for many years.

2. We are experienced for 10 years.

3. We can offer a various kind of bearing with high quality:Z1V1,Z2V2,Z3V3 and best price

Q:How is the quality of your products?

A:The same quality, we have lower price.The same price,we have better quality.

Q:Except Full complement Cylindrical roller bearing,what other main bearing do you have?

A:Taper Roller Bearing,Thrust roller bearing,Spherical roller bearing,Deep groove ball bearing,Angular contact ball bearing etc.

Q:Can I get Full complement Cylindrical roller bearing free samples?

A:We will charge a little sample fee for our regular designs or customized ones, These charges will be refunded to you when your mass production order is confirmed.

Q:Can you make the products as our requirement?

A:We have more than 10 year’s OEM experience. We supply products fo more than 300 automobile parts factories.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Medium and Large(120-190mm) |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do radial bearings contribute to reduced friction and smooth rotation in machinery?

Radial bearings play a crucial role in reducing friction and promoting smooth rotation in machinery. Their design and construction contribute to minimizing contact between moving parts, optimizing efficiency, and enhancing overall performance. Here is a detailed explanation of how radial bearings achieve reduced friction and smooth rotation:

1. Rolling Elements:

Radial bearings typically incorporate rolling elements, such as balls or rollers, between the inner and outer races. These rolling elements reduce friction compared to sliding contact between surfaces. As the bearing rotates, the rolling elements roll instead of slide, resulting in lower frictional forces and reduced energy loss. The rolling action of the elements contributes to smoother rotation and improved efficiency.

2. Lubrication:

Lubrication is essential for reducing friction and ensuring smooth rotation in radial bearings. Lubricants, such as oils or greases, are used to create a thin film between the rolling elements and raceways. This lubricating film separates the surfaces, minimizing direct contact and friction. The lubricant also helps to dissipate heat generated during operation, preventing excessive temperature rise and potential damage to the bearing. Proper lubrication is critical to maintaining low friction and promoting smooth rotation in radial bearings.

3. Bearing Clearance and Preload:

The clearance or preload adjustment in radial bearings also contributes to reduced friction and smooth rotation. Bearing clearance refers to the intentional space left between the rolling elements and raceways, allowing for thermal expansion and accommodating operating conditions. Adequate clearance ensures that the bearing components can move freely without excessive interference, minimizing friction. On the other hand, preload is a controlled axial force applied to eliminate clearance and maintain a slight internal load on the bearing. Preload helps to reduce internal clearances, improve stiffness, and minimize any potential play or vibration, resulting in smoother rotation.

4. Bearing Material and Surface Finish:

The choice of bearing material and surface finish significantly impacts friction and smooth rotation. Radial bearings are commonly made from materials such as steel, ceramic, or polymer composites. These materials offer excellent hardness, wear resistance, and low friction characteristics. Additionally, the surfaces of the bearing components undergo precise machining and finishing processes to achieve smoothness and minimize surface irregularities. The combination of suitable materials and high-quality surface finishes promotes reduced friction and smooth rotation in radial bearings.

5. Bearing Design and Internal Geometry:

The design and internal geometry of radial bearings are optimized to minimize friction and promote smooth rotation. Factors such as the number and size of rolling elements, the contact angle, and the curvature of the raceways are carefully engineered to ensure proper load distribution and minimize stress concentrations. Well-designed bearing cages also help maintain the correct spacing and alignment of the rolling elements, reducing friction and ensuring smooth rotation. The overall design and geometry of radial bearings are crucial for achieving optimal performance and minimizing frictional losses.

6. Precision Manufacturing:

Radial bearings are manufactured with high precision to achieve tight tolerances and minimize variations in dimensions. Precision manufacturing processes, such as grinding and superfinishing, ensure that the bearing components have accurate shapes and smooth surfaces. This precision manufacturing contributes to reduced friction and smooth rotation by minimizing irregularities and imperfections that can cause excess friction or vibration.

In summary, radial bearings contribute to reduced friction and smooth rotation in machinery through the use of rolling elements, proper lubrication, optimized bearing clearance or preload, suitable materials and surface finishes, well-engineered designs, and precision manufacturing. These factors work together to minimize contact, reduce frictional forces, and ensure efficient and reliable operation of machinery and equipment.

Can radial bearings be customized or modified for unique industrial needs?

Radial bearings can indeed be customized or modified to meet unique industrial needs. Manufacturers often offer customization options to provide bearings that are tailored to specific application requirements. Customization allows for the optimization of various aspects of the bearing, such as size, design, materials, lubrication, and sealing, among others. Here’s a detailed explanation of the customization and modification possibilities for radial bearings:

1. Size and Design:

Radial bearings can be customized in terms of size and design to fit specific space constraints or load requirements. Manufacturers can adjust the dimensions of the bearing, such as the bore diameter, outer diameter, or width, to match the application’s unique specifications. Additionally, the bearing design can be modified to accommodate specific performance needs, such as increased load capacity, enhanced stiffness, or improved rotational speed capabilities.

2. Materials:

The choice of materials used in radial bearings can be customized based on the application’s needs. Different materials offer varying levels of strength, corrosion resistance, temperature resistance, and other properties. For example, in high-temperature environments, bearings can be customized with heat-resistant materials, such as ceramic or high-temperature alloys, to ensure reliable operation. Similarly, for applications where corrosion is a concern, bearings can be customized with corrosion-resistant coatings or materials.

3. Lubrication:

Radial bearings can be customized in terms of lubrication requirements. The lubrication type and quantity can be modified to suit specific operating conditions. For instance, bearings operating in high-speed applications may require specialized lubricants that can withstand high temperatures and provide sufficient lubrication film thickness. Customized lubrication solutions can help optimize bearing performance, reduce friction, and extend the bearing’s service life.

4. Sealing and Protection:

Bearing customization can include modifications to the sealing and protection features. Seals or shields can be customized to provide enhanced protection against contaminants, moisture, or other environmental factors. By choosing the appropriate sealing solution, the ingress of dust, dirt, or liquids can be minimized, improving the bearing’s reliability and longevity. Customized sealing options can also help reduce maintenance requirements and prevent premature failure.

5. Specialized Coatings:

In certain industrial applications, specialized coatings can be applied to radial bearings to enhance their performance. These coatings can provide benefits such as increased wear resistance, reduced friction, improved corrosion resistance, or enhanced operating characteristics under specific conditions. Customized coatings can be designed based on the specific application needs, ensuring optimal performance and longevity of the bearings in demanding environments.

6. Mounting and Fit:

Customization of radial bearings can include modifications to the mounting and fit requirements. For unique applications where standard mounting methods are not suitable, manufacturers can customize the bearing’s mounting features to ensure proper fit and alignment within the system. This may involve modifications to the bearing’s outer ring, inner ring, or flange design to accommodate specific mounting arrangements or requirements.

7. Application-Specific Considerations:

Manufacturers of radial bearings are often willing to work closely with customers to understand their unique industrial needs and develop customized solutions. By considering application-specific factors such as load conditions, operating environment, speed requirements, and space limitations, manufacturers can tailor the design and specifications of radial bearings to provide optimal performance and reliability.

It is important to note that customization of radial bearings may involve additional costs and lead time compared to off-the-shelf bearings. However, the benefits of having bearings specifically tailored to the application’s requirements often outweigh these considerations, as they can result in improved performance, increased service life, and reduced downtime.

Overall, radial bearings can be customized or modified to meet unique industrial needs, allowing for the optimization of various parameters to ensure optimal performance, reliability, and longevity in specific applications. Collaborating with bearing manufacturers or industry experts can help identify the customization possibilities and develop tailored solutions that address the specific requirements of the industrial application.

What are the eco-friendly or sustainable aspects of radial bearing materials?

Radial bearing materials play a crucial role in determining the environmental impact and sustainability of the bearings. Several aspects of radial bearing materials contribute to their eco-friendliness and sustainability. Here’s a detailed explanation of these aspects:

1. Material Selection:

The choice of bearing material can have a significant impact on its environmental footprint. Opting for materials that are eco-friendly and sustainable is important. Some materials commonly used in radial bearings, such as steel, have high recycling rates and can be recycled at the end of their life cycle. This reduces the demand for new raw materials and minimizes waste generation. Additionally, selecting materials that are abundant and easily sourced further enhances the sustainability of radial bearings.

2. Recyclability:

Radial bearings made from recyclable materials are considered environmentally friendly. When bearings reach the end of their useful life, they can be recycled, and the materials can be repurposed for manufacturing new bearings or other products. Recycling reduces the need for virgin materials extraction, conserves resources, and reduces energy consumption and greenhouse gas emissions associated with the production of new materials. Choosing bearing materials that are easily recyclable promotes a circular economy and minimizes waste generation.

3. Reduced Environmental Impact:

Some radial bearing materials have a lower environmental impact compared to others. For example, selecting materials with lower carbon footprints or materials that require less energy-intensive manufacturing processes can contribute to sustainability. Materials like ceramic or composite bearings often have lower energy requirements during production compared to traditional steel bearings. By reducing energy consumption and associated emissions, these materials help mitigate the environmental impact of bearing manufacturing.

4. Lubrication and Friction Reduction:

The choice of bearing material can also influence the lubrication requirements and friction levels. Bearings made from materials with inherent self-lubricating properties or low friction coefficients can reduce the need for external lubrication or the use of lubricants with potential environmental impacts. Self-lubricating materials such as polymers or certain composites can minimize the use of oil or grease lubricants, which can be environmentally harmful if not managed properly. Reduced lubrication requirements contribute to sustainable bearing operation by minimizing lubricant consumption and potential contamination risks.

5. Extended Service Life:

Using durable and long-lasting bearing materials helps extend the service life of the bearings. Bearings that require less frequent replacement or maintenance have a positive impact on sustainability. By reducing the frequency of bearing replacements, less waste is generated, and the consumption of raw materials is minimized. Additionally, extending the service life of bearings reduces the need for energy-intensive manufacturing processes associated with frequent replacements, further reducing the environmental impact.

6. Energy Efficiency:

Radial bearing materials can contribute to energy efficiency in mechanical systems. Materials with low friction coefficients and high wear resistance properties help minimize energy losses due to friction and improve overall system efficiency. By reducing energy consumption, sustainable bearing materials support energy conservation efforts and contribute to the reduction of greenhouse gas emissions associated with energy production.

7. Compliance with Environmental Regulations:

Eco-friendly and sustainable radial bearing materials often comply with environmental regulations and standards. These materials are designed to meet specific requirements regarding the use of hazardous substances, waste generation, and disposal. Compliance with regulations such as the Restriction of Hazardous Substances (RoHS) directive ensures that bearing materials are free from harmful substances, protecting human health and the environment.

8. Life Cycle Assessment:

A comprehensive life cycle assessment (LCA) of bearing materials can provide insights into their environmental impact. LCA evaluates the environmental effects associated with a product throughout its entire life cycle, from raw material extraction to end-of-life disposal. Conducting LCAs helps identify areas of improvement, optimize manufacturing processes, and select materials with lower environmental impacts.

By considering these eco-friendly and sustainable aspects of radial bearing materials, manufacturers and end-users can make informed choices that minimize their environmental footprint. Sustainable bearing materials contribute to resource conservation, waste reduction, energy efficiency, and compliance with environmental regulations, fostering a more sustainable and environmentally responsible industrial ecosystem.

editor by CX 2024-03-28