Product Description

6206 Auto bearing/vehicle bearing/wheeler bearing/motorcycle spare parts/auto parts/Conveyor bearing /ceiling fan bearings/radial bearing

Product Description

Deep groove bearing Specification

1.Bearing Factory more than 20 years

2.Own brand :F&D bearing ,CBB brand look for distributor and agents.

3.OEM Accepted.

4.ISO9001:2000. TS16949.

The type of Conveyor bearing 6203 Transmission Parts bearing treadmill bearings high precision rolling bearing component materials used will determine the life span, reliability and performance of the bearings. However, there are many factors affecting the performance of the bearings which include the selection of the load carrying capacity, the rolling contact conditions, and the cleanliness of the operating environment and the dimensional stability of the bearing components.

Detailed Photos

Product Parameters

Fuda bearing company has adopted the carbon-chromium steel material(Gcr15) in our productionof the bearing.

| Bearing No. | I.D | O.D | W | Loading Rating(KN) | Steel Ball Parameter | Max Speed | ||||||

| d | D | B | Dynamic | Static | No. | Size | Grease | Oil | ||||

| mm | inch | mm | inch | mm | inch | Cr | Cor | mm | r/min | r/min | ||

| 6000 | 10 | 0.3937 | 26 | 1.5716 | 8 | 0.3150 | 4.55 | 1.95 | 7 | 4.763 | 29000 | 34000 |

| 6001 | 12 | 0.4724 | 28 | 1.1571 | 8 | 0.3150 | 5.10 | 2.39 | 8 | 4.763 | 26000 | 30000 |

| 6002 | 15 | 0.5906 | 32 | 1.2598 | 9 | 0.3543 | 5.60 | 2.84 | 9 | 4.763 | 22000 | 26000 |

| 6003 | 17 | 0.6693 | 35 | 1.3780 | 10 | 0.3937 | 6.80 | 3.35 | 10 | 4.763 | 20000 | 24000 |

| 6004 | 20 | 0.7874 | 42 | 1.6535 | 12 | 0.4724 | 9.40 | 5.05 | 9 | 6.350 | 18000 | 21000 |

| 6005 | 25 | 0.9843 | 47 | 1.8504 | 12 | 0.4724 | 10.10 | 5.85 | 10 | 6.350 | 15000 | 18000 |

| 6006 | 30 | 1.1811 | 55 | 2.1654 | 13 | 0.5118 | 13.20 | 8.30 | 11 | 7.144 | 13000 | 15000 |

| 6007 | 35 | 1.3780 | 62 | 2.4409 | 14 | 0.5512 | 16.00 | 10.30 | 11 | 7.938 | 12000 | 14000 |

| 6008 | 40 | 1.5748 | 68 | 2.6772 | 15 | 0.5906 | 16.80 | 11.50 | 12 | 7.938 | 10000 | 12000 |

| 6009 | 45 | 1.7717 | 75 | 2.9528 | 16 | 0.6299 | 21.00 | 15.10 | 12 | 8.731 | 9200 | 11000 |

| 6571 | 50 | 1.9685 | 80 | 3.1496 | 16 | 0.6299 | 21.80 | 16.60 | 13 | 8.731 | 8400 | 9800 |

| 6011 | 55 | 2.1654 | 90 | 3.5433 | 18 | 0.7087 | 28.30 | 21.20 | 12 | 11.000 | 7700 | 9000 |

| 6012 | 60 | 2.3622 | 95 | 3.7402 | 18 | 0.7087 | 29.50 | 23.20 | 13 | 11.000 | 7000 | 8300 |

| 6013 | 65 | 2.5591 | 100 | 3.9370 | 18 | 0.7087 | 30.50 | 25.20 | 13 | 11.112 | 6500 | 7700 |

| 6014 | 70 | 2.7559 | 110 | 4.3307 | 20 | 0.7874 | 38.00 | 31.00 | 13 | 12.303 | 6100 | 7100 |

| 6015 | 75 | 2.9528 | 115 | 4.5276 | 20 | 0.7874 | 39.50 | 33.50 | 14 | 12.303 | 5700 | 6700 |

| 6016 | 80 | 3.1496 | 125 | 4.9213 | 22 | 0.8661 | 47.50 | 40.00 | 14 | 13.494 | 5300 | 6200 |

| Bearing No. | I.D | O.D | W | Loading Rating(KN) | Steel Ball Parameter | Max Speed | ||||||

| d | D | B | Dynamic | Static | No. | Size | Grease | Oil | ||||

| mm | inch | mm | inch | mm | inch | Cr | Cor | mm | r/min | r/min | ||

| 6200 | 10 | 0.3937 | 30 | 1.1811 | 9 | 0.3543 | 5.10 | 2.39 | 8 | 4.763 | 25000 | 30000 |

| 6201 | 12 | 0.4724 | 32 | 1.2598 | 10 | 0.3937 | 6.10 | 2.75 | 7 | 5.953 | 22000 | 26000 |

| 6202 | 15 | 0.5906 | 35 | 1.3780 | 11 | 0.4331 | 7.75 | 3.60 | 8 | 5.953 | 19000 | 23000 |

| 6203 | 17 | 0.6693 | 40 | 1.5748 | 12 | 0.4724 | 9.60 | 4.60 | 8 | 6.747 | 18000 | 21000 |

| 6204 | 20 | 0.7874 | 47 | 1.8504 | 14 | 0.5512 | 12.80 | 6.65 | 8 | 7.938 | 16000 | 18000 |

| 6205 | 25 | 0.9843 | 52 | 2.571 | 15 | 0.5906 | 14.00 | 7.85 | 9 | 7.938 | 13000 | 15000 |

| 6206 | 30 | 1.1811 | 62 | 2.4409 | 16 | 0.6299 | 19.50 | 11.30 | 9 | 9.525 | 11000 | 13000 |

| 6207 | 35 | 1.3780 | 72 | 2.8346 | 17 | 0.6693 | 25.70 | 15.30 | 9 | 11.112 | 9800 | 11000 |

| 6208 | 40 | 1.5748 | 80 | 3.1496 | 18 | 0.7087 | 29.10 | 17.80 | 9 | 12.000 | 8700 | 10000 |

| 6209 | 45 | 1.7717 | 85 | 3.3465 | 19 | 0.7480 | 32.50 | 20.40 | 10 | 12.000 | 7800 | 9200 |

| 6210 | 50 | 1.9685 | 90 | 3.5433 | 20 | 0.7874 | 35.00 | 23.20 | 10 | 12.700 | 7100 | 8300 |

| 6211 | 55 | 2.1654 | 100 | 3.9370 | 21 | 0.8268 | 43.50 | 29.20 | 10 | 14.288 | 6400 | 7600 |

| 6212 | 60 | 2.3622 | 110 | 4.3307 | 22 | 0.8661 | 52.50 | 36.00 | 10 | 15.081 | 6000 | 7000 |

| 6213 | 65 | 2.5591 | 120 | 4.7244 | 23 | 0.9055 | 57.50 | 40.00 | 10 | 16.669 | 5500 | 6500 |

| 6214 | 70 | 2.7559 | 125 | 4.9213 | 24 | 0.9449 | 62.00 | 44.00 | 11 | 16.462 | 5100 | 6000 |

| 6215 | 75 | 2.9528 | 130 | 5.1181 | 25 | 0.9843 | 66.00 | 49.50 | 11 | 17.462 | 4800 | 5600 |

| 6216 | 80 | 3.1496 | 140 | 5.5118 | 26 | 1.5716 | 72.50 | 53.00 | 11 | 18.256 | 4500 | 5300 |

| 6217 | 85 | 3.3465 | 150 | 5.9055 | 28 | 1.1571 | 83.50 | 64.00 | 11 | 19.844 | 4200 | 5000 |

| 6218 | 90 | 3.5433 | 160 | 6.2992 | 30 | 1.1811 | 96.00 | 71.50 | 10 | 22.225 | 4000 | 4700 |

| Bearing No. | I.D | O.D | W | Loading Rating(KN) | Steel Ball Parameter | Max Speed | ||||||

| d | D | B | Dynamic | Static | No. | Size | Grease | Oil | ||||

| mm | inch | mm | inch | mm | inch | Cr | Cor | mm | r/min | r/min | ||

| 6300 | 10 | 0.3937 | 35 | 1.3780 | 11 | 0.4331 | 8.20 | 3.50 | 6 | 7.144 | 23000 | 27000 |

| 6301 | 12 | 0.4724 | 37 | 1.4567 | 12 | 0.4724 | 9.70 | 4.20 | 6 | 7.938 | 20000 | 24000 |

| 6302 | 15 | 0.5906 | 42 | 1.6535 | 13 | 0.5118 | 11.40 | 5.45 | 7 | 7.938 | 17000 | 21000 |

| 6303 | 17 | 0.6693 | 47 | 1.8504 | 14 | 0.5512 | 13.50 | 6.55 | 7 | 8.731 | 16000 | 19000 |

| 6304 | 20 | 0.7874 | 52 | 2.571 | 15 | 0.5906 | 15.90 | 7.90 | 7 | 9.525 | 14000 | 27000 |

| 6305 | 25 | 0.9843 | 62 | 2.4409 | 17 | 0.6693 | 21.20 | 10.90 | 7 | 11.500 | 12000 | 14000 |

| 6306 | 30 | 1.1811 | 72 | 2.8346 | 19 | 0.7480 | 26.70 | 15.00 | 8 | 12.000 | 10000 | 12000 |

| 6307 | 35 | 1.3780 | 80 | 3.1496 | 21 | 0.8268 | 33.50 | 19.10 | 8 | 13.494 | 8800 | 10000 |

| 6308 | 40 | 1.5748 | 90 | 3.5433 | 23 | 0.9055 | 40.50 | 24.00 | 8 | 15.081 | 7800 | 9200 |

| 6309 | 45 | 1.7717 | 100 | 3.9370 | 25 | 0.9843 | 53.00 | 32.00 | 8 | 17.462 | 7000 | 8200 |

| 6310 | 50 | 1.9685 | 110 | 4.3307 | 27 | 1.0630 | 62.00 | 38.50 | 8 | 19.050 | 6400 | 7500 |

| 6311 | 55 | 2.1654 | 120 | 4.7244 | 29 | 1.1417 | 71.50 | 45.00 | 8 | 20.638 | 5800 | 6800 |

| 6312 | 60 | 2.3622 | 130 | 5.1181 | 31 | 1.2205 | 82.00 | 52.00 | 8 | 22.225 | 5400 | 6300 |

| 6313 | 65 | 2.5591 | 140 | 5.5118 | 33 | 1.2992 | 92.50 | 60.00 | 8 | 24.000 | 4900 | 5800 |

| 6314 | 70 | 2.7559 | 150 | 5.9055 | 35 | 1.3780 | 104.00 | 68.00 | 8 | 25.400 | 4600 | 5400 |

| 6315 | 75 | 2.9528 | 160 | 6.2992 | 37 | 1.4567 | 113.00 | 77.00 | 8 | 26.988 | 4300 | 5000 |

| 6316 | 80 | 3.1496 | 170 | 6.6929 | 39 | 1.5354 | 123.00 | 86.50 | 8 | 28.575 | 4000 | 4700 |

Packaging & Shipping

Packaging & Shipping for Conveyor bearing 6203 Transmission Parts bearing treadmill bearings

| Packaging Detail | 1.Industrial Exporting Package with anti-tarnish paper/Carton/Pallet 2. Individual plastic/Carton/pallet 3. As the customers’ requirements |

| Delivery Detail | 30-45 days for normal order |

Installation Instructions

One of the leading bearing manufacturers and exporters in China

China CZPT Bearing Corporation was established in 1996 and is 1 of the leading bearing manufacturers and exporters in China. CZPT specializes in the design and production of high quality, high precision deep groove ball bearings and pillow block bearings. At present, the Corporation has more than 1,000 employees, a fixed assets of 1.05 billion yuan, and produces 250 million sets of bearings annually. In 2571, the Corporation achieved bearing sales of 650 million yuan. The Corporation’s products are widely used in more than 50 countries and regions under 2 independent brands, namely “F&D” and “FLATE”. Now CZPT created new brand “CBB”.

Research and Development

Since 2008, the Corporation has set up a Research & Development Center equipped with multiple laboratories used for precision measurement, mechanical testing, lifespan testing, and physicochemical testing, to continuously upgrade its skills and raise its manufacturing standard and product’s precision. Our workshops are installed with a series of advanced numerically-controlled, grinding and assembly equipment that utilize centralized filtration and cooling systems. Together with the production equipment suppliers, we developed these grinding, ultra-precision, fully automated integrated production lines, and own the intellectual property rights. The precision level of the products are at P5 level and above, with noise level CZPT Z4, V4 and above. Some of our projects have exceeded the 30% precision reserves. Our products are widely used in electric motors, automobiles, motorcycles, household appliances, textile, electric tools and water pump equipment industries, both locally and globally.

Company Profile

Why Choose US

About US

Fuda Bearing Corporation Co., Ltd. was founded in 1996, and became 1 of Chinese largest bearing manufacturers and exporters. which specializes in designing and producing deep groove ball bearings, pillow block bearings with high quality & precision. After more than 10 years’hard work, CZPT has developed into a high-tech company that is capable of bearing research & development, manufacturing, and marketing. The Corporation consists of 5 subsidiaries including ZHangZhoug CZPT Bearing Co., Ltd, Flate Precision Tech. Co.,Ltd, HangZhou Unit Machinery Co., Ltd, HangZhou Oyat Bearing Co.,Ltd, CZPT Bearing Corporation Imp.& Exp.Co.Ltd. Now CZPT has employees more than 1000 with the fixed assets of RMB 1.05 billion. And the annual production capacity can reach 25 million sets. In 2571, the bearing sales volume was RMB 650 millions.Besides it creates 2 self-owned brands called F&D and FLATE.Now we use new brand “CBB bearing” instead of Flate which can be easy keep memory for our customer. The products are well received in more than 50 countries and regions.

Our Advantages

Quality Assurance

Product quality is the lifeline of an enterprise. In order to possessing the leading technology, our company implements the quality control system and establishes a technical and strict inspection team. As per the regulation of three-dimensional management and multiple checks, each product was inspected by the producer, inspector, inspection department and quality department elaborately, especially to the important inspection items and precision inspection item.

Our Service

High quality, good credit and excellent service are the tenet of our company. Customers’satisfaction is our lifeline, as well as our highest honor. We will do our best to meet your requirements, and will do better in the future.

Our Trade Partner

CONTACT US

|

PENGQIAO INDUSTRIAL PARK HENGHE |

|

| Web: | fudabearing |

Thanks for visiting our time review 6206 Auto bearing/vehicle bearing/wheeler bearing/motorcycle spare parts/auto parts/Conveyor bearing /ceiling fan bearings/radial bearing .

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Offer after sell service |

|---|---|

| Warranty: | 2 years+ |

| Type: | Engine Bearing |

| Samples: |

US$ 150/Piece

1 Piece(Min.Order) | Order Sample 10pcs sample

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are radial bearings, and how are they used in mechanical applications?

Radial bearings are a type of rolling element bearing used in mechanical applications to support radial loads. They are designed to primarily handle forces that are perpendicular to the shaft’s axis, known as radial loads, although they can also withstand limited axial (thrust) loads. Radial bearings are widely used in various mechanical systems where rotational motion is involved. Here is a detailed explanation of radial bearings and their applications:

1. Structure and Components:

Radial bearings consist of several key components. The inner ring is mounted on the rotating shaft, while the outer ring remains stationary. Between the inner and outer rings, there are rolling elements, such as steel balls or cylindrical rollers. These rolling elements are evenly spaced and held in position by a cage or retainer, which prevents their contact and ensures smooth rolling motion. The inner and outer rings, along with the rolling elements and cage, work together to support and distribute the load applied to the bearing.

2. Radial Load Support:

The primary function of radial bearings is to support radial loads. Radial loads are forces that act perpendicular to the shaft’s axis, such as the weight of a rotating shaft or the force exerted by a belt or pulley system. Radial bearings are designed to distribute these loads evenly across the rolling elements, minimizing friction and allowing smooth rotation. The rolling elements roll between the inner and outer rings, absorbing and transmitting the radial load to the stationary outer ring, which then transfers the load to the surrounding structure.

3. Axial Load Capacity:

While radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as the force generated by a thrusting or pushing motion. The axial load capacity of radial bearings is lower compared to dedicated thrust bearings, but they can handle moderate axial loads that may be present in certain applications. It is important to consider the axial load capacity of the specific radial bearing when selecting it for a mechanical application.

4. Versatility and Wide Range of Applications:

Radial bearings are versatile and find applications in a wide range of mechanical systems. They are commonly used in machinery and equipment such as electric motors, pumps, fans, conveyors, automotive components, and industrial machinery. Radial bearings are crucial for providing support and facilitating smooth rotation in these applications. They are able to handle various operating conditions, speeds, and loads, making them suitable for both light-duty and heavy-duty applications.

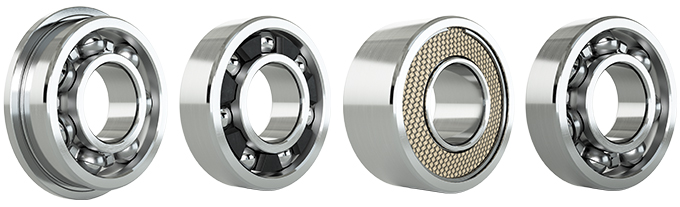

5. Different Types of Radial Bearings:

There are different types of radial bearings available to suit different application requirements. Some common types include:

– Deep Groove Ball Bearings: These are the most common type of radial bearings, with deep raceway grooves to accommodate high radial and axial loads.

– Angular Contact Ball Bearings: These bearings have raceways designed to handle both radial and axial loads, offering high-speed capabilities and precise axial positioning.

– Cylindrical Roller Bearings: These bearings have cylindrical rollers instead of balls and can handle higher radial loads compared to ball bearings.

– Tapered Roller Bearings: These bearings have tapered raceways, enabling them to handle both radial and axial loads, particularly in applications with combined loads.

– Spherical Roller Bearings: These bearings have barrel-shaped rollers and can accommodate misalignment and heavy radial loads in applications with high shock and vibration.

6. Lubrication and Maintenance:

Proper lubrication is crucial for the performance and longevity of radial bearings. Lubricants reduce friction, dissipate heat, and prevent metal-to-metal contact between the rolling elements and raceways. Lubrication methods can vary depending on the specific bearing design and application. Regular maintenance, including lubricant inspection and replenishment, is important to ensure optimal bearing operation and prevent premature wear or failure.

In summary, radial bearings are rolling element bearings used in mechanical applications to support radial loads. They consist of inner and outer rings, rolling elements, and a cage. Radial bearings primarily handle forces perpendicular to the shaft’s axis and distribute the load evenly across the rolling elements. They are versatile and find applications in various mechanical systems, offering support and facilitating smooth rotation. Proper lubrication and maintenance are essential for their reliable operation and longevity.

What is the impact of proper lubrication on the performance and lifespan of radial bearings?

Proper lubrication plays a crucial role in the performance and lifespan of radial bearings. It is essential to provide adequate lubrication to minimize friction, reduce wear, and ensure reliable operation. Here’s a detailed explanation of the impact of proper lubrication on the performance and lifespan of radial bearings:

1. Friction Reduction:

Proper lubrication forms a thin film of lubricant between the rolling elements and raceways of the bearing. This lubricating film reduces friction and minimizes the resistance to rotation, allowing the bearing to operate smoothly. Reduced friction results in lower energy consumption, decreased heat generation, and improved overall efficiency of the bearing system.

2. Wear Prevention:

Effective lubrication helps prevent wear and damage to the bearing surfaces. The lubricant forms a protective layer that separates the rolling elements from the raceways, preventing direct metal-to-metal contact. This separation minimizes wear, surface fatigue, and the risk of premature bearing failure. Proper lubrication significantly extends the lifespan of radial bearings by preserving their working surfaces.

3. Temperature Control:

Lubrication plays a critical role in controlling the operating temperature of radial bearings. The lubricant absorbs and dissipates heat generated during operation, preventing excessive temperature rise. Adequate lubrication helps maintain the bearing within the optimal temperature range, reducing the risk of thermal damage and preserving the integrity of the bearing components.

4. Contamination Protection:

Proper lubrication forms a barrier against contaminants such as dirt, dust, moisture, and particles. The lubricant acts as a protective shield, preventing these contaminants from entering the bearing and causing damage. Effective lubrication helps maintain the cleanliness of the bearing, reducing the risk of abrasive wear, corrosion, and other forms of contamination-induced failure.

5. Corrosion Prevention:

Lubrication helps prevent corrosion and rust formation on the bearing surfaces. The lubricant forms a protective film that acts as a barrier, preventing moisture and corrosive agents from reaching the metal surfaces. By inhibiting corrosion, proper lubrication enhances the longevity and reliability of radial bearings, particularly in demanding environments or applications exposed to moisture and corrosive substances.

6. Noise and Vibration Reduction:

Effective lubrication contributes to reducing noise and vibration levels in radial bearings. The lubricant absorbs and dampens the vibrations generated during operation, resulting in smoother and quieter bearing performance. Proper lubrication helps minimize noise pollution, enhances user comfort, and improves the overall operation of machinery and equipment.

7. Load Capacity Enhancement:

Appropriate lubrication can enhance the load-carrying capacity of radial bearings. The lubricant’s lubricating properties and film thickness help distribute the applied loads evenly across the bearing surfaces, reducing stress concentrations. This allows the bearing to support higher loads and handle heavier operating conditions without compromising its performance or lifespan.

8. Reliability and Longevity:

Overall, proper lubrication significantly enhances the reliability and longevity of radial bearings. It minimizes wear, reduces friction, prevents damage, controls temperature, protects against contamination, inhibits corrosion, reduces noise and vibration, and improves load-carrying capacity. By ensuring optimal lubrication conditions, the performance and lifespan of radial bearings are maximized, leading to improved equipment uptime, reduced maintenance requirements, and increased operational efficiency.

In conclusion, proper lubrication is essential for achieving optimal performance, longevity, and reliability of radial bearings. It minimizes friction, reduces wear, controls temperature, protects against contamination and corrosion, and enhances load-carrying capacity. Regular monitoring and maintenance of lubrication conditions are crucial to ensure the continued smooth operation and extended lifespan of radial bearings.

How do innovations and advancements in radial bearing technology impact their use?

Innovations and advancements in radial bearing technology have a significant impact on their use in various industries and applications. These advancements drive improvements in performance, reliability, efficiency, and versatility of radial bearings. Here’s a detailed explanation of how innovations and advancements in radial bearing technology impact their use:

1. Enhanced Performance:

Advancements in radial bearing technology lead to improved performance characteristics. This includes increased load capacities, higher rotational speeds, reduced friction, and enhanced stiffness. These improvements allow radial bearings to handle more demanding loads and operate in high-speed applications more effectively. Enhanced performance enables the use of radial bearings in a wider range of industrial applications, contributing to increased efficiency and productivity.

2. Extended Service Life:

Innovations in bearing materials, lubrication systems, and surface treatments result in extended service life for radial bearings. New materials with superior wear resistance and corrosion resistance properties allow bearings to withstand harsh environments and reduce the risk of premature failure. Advanced lubrication techniques, such as self-lubricating or solid lubricant coatings, minimize friction and wear, further prolonging the bearing’s service life. The ability of radial bearings to operate reliably for longer periods translates into reduced maintenance requirements and downtime.

3. Improved Reliability:

Advancements in radial bearing technology enhance their overall reliability. New designs and manufacturing techniques ensure consistent quality, dimensional accuracy, and precise tolerances, resulting in reliable performance under varying operating conditions. The use of advanced simulation and testing methods enables better prediction and understanding of bearing behavior, allowing for optimized designs and improved reliability. Enhanced reliability reduces the risk of unexpected bearing failures, which can lead to costly downtime and equipment damage.

4. Higher Efficiency:

Innovations in radial bearing technology contribute to higher efficiency in mechanical systems. Reduced friction and improved lubrication techniques minimize energy losses within the bearing, resulting in improved overall system efficiency. Bearings with lower friction help reduce power consumption and improve energy utilization, making them particularly beneficial in applications where energy efficiency is a priority, such as electric motors or automotive drivetrains.

5. Miniaturization and Compact Designs:

Advancements in radial bearing technology enable the development of smaller and more compact bearing designs. This is particularly important in industries where space constraints are a significant consideration. Miniaturized bearings allow for the design of smaller and lighter equipment without compromising performance. They find applications in industries such as aerospace, robotics, medical devices, and electronics, where size and weight reduction are crucial.

6. Specialized Applications:

Innovations in radial bearing technology have led to the development of specialized bearings tailored for specific applications. For example, advancements in bearing materials and designs have resulted in bearings capable of operating in extreme temperature or high-vibration environments. Specialized bearings designed for specific industries, such as the food and beverage or pharmaceutical sectors, meet stringent regulatory requirements regarding hygiene and contamination prevention. These specialized bearings expand the range of applications where radial bearings can be used effectively.

7. Integration with Sensor Technologies:

Advancements in sensor technologies have facilitated the integration of condition monitoring and predictive maintenance capabilities into radial bearings. Bearings equipped with sensors can provide real-time data on factors such as temperature, vibration, and load conditions. This allows for proactive maintenance and early detection of potential issues, enabling timely interventions to prevent unplanned downtime and optimize equipment performance.

8. Cost Optimization:

While innovations and advancements in radial bearing technology often involve initial investments in research and development, they can lead to long-term cost savings. Improved performance, extended service life, and reduced maintenance requirements result in lower operational costs over the bearing’s lifetime. Additionally, advancements in manufacturing processes and economies of scale may contribute to more affordable bearing options, making advanced radial bearing technology accessible to a wider range of applications.

By continually pushing the boundaries of radial bearing technology, innovations and advancements have a profound impact on their use across various industries. Enhanced performance, extended service life, improved reliability, higher efficiency, miniaturization, specialized applications, integration with sensor technologies, and cost optimization are some of the key benefits that result from these advancements. As a result, engineers and designers have access to a wider range of bearing options to meet the evolving needs of modern industrial applications.

editor by CX 2024-01-16