Product Description

Company Profile

ZheJiang Furlante Bearing Technology Co is a professional bearing manufacturer with factory and trade. Our company is mainly engaged in deep groove ball bearings,apered roller bearings,External spherical housing bearings,Thrust ball bearings,Linear CZPT bearing system. We have a self-developed team to design and improve the bearings. To meet the needs of different customers. we provide oem and odm,and we have a perfect quality inspection system and professional after-sales service team. we will provide you the best products and services with the most reasonable price.

Product Description

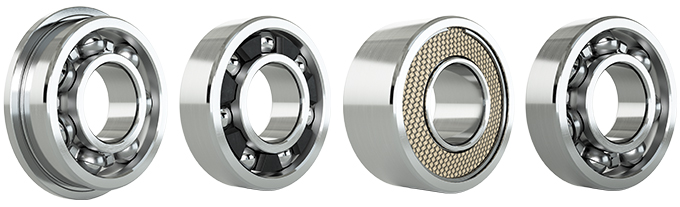

Deep groove ball bearing

| Model | d mm | D mm | H mm | W kg |

| 6000 | 10 | 26 | 8 | 0.019 |

| 6001 | 12 | 38 | 8 | 0.571 |

| 6002 | 15 | 32 | 9 | 0.03 |

| 6003 | 17 | 35 | 10 | 0.04 |

| 6004 | 20 | 42 | 12 | 0.069 |

| 6005 | 25 | 47 | 12 | 0.08 |

| 6006 | 30 | 55 | 13 | 0.116 |

| 6007 | 35 | 62 | 14 | 0.155 |

| 6008 | 40 | 68 | 15 | 0.185 |

| 6009 | 45 | 75 | 16 | 0.231 |

| 6571 | 50 | 80 | 16 | 0.25 |

| 6011 | 55 | 90 | 18 | 0.362 |

| 6012 | 60 | 95 | 18 | 0.385 |

| 6013 | 65 | 100 | 18 | 0.408 |

| 6014 | 70 | 110 | 20 | 0.62 |

| 6015 | 75 | 115 | 20 | 0.63 |

| 6016 | 80 | 125 | 22 | 0.86 |

| 6017 | 85 | 130 | 22 | 0.94 |

| 6018 | 90 | 140 | 24 | 1.38 |

| 6019 | 95 | 145 | 24 | 1.5 |

| 6571 | 100 | 150 | 24 | 1.63 |

| 6571 | 110 | 170 | 28 | 2.35 |

| 6571 | 120 | 180 | 28 | 2.62 |

| 6026 | 130 | 200 | 33 | 4.55 |

| 6571 | 140 | 210 | 33 | 4.21 |

| 6030 | 150 | 210 | 33 | 3.9 |

| 6032 | 160 | 240 | 38 | 5.89 |

| 6034 | 170 | 260 | 42 | 6.5 |

| 6036 | 180 | 280 | 46 | 8.51 |

| 6038 | 190 | 290 | 46 | 8.86 |

| 6040 | 200 | 310 | 51 | 11.64 |

| 6044 | 220 | 340 | 56 | 18.4 |

| 6048 | 240 | 360 | 56 | 19.6 |

| 6052 | 260 | 400 | 65 | 28.8 |

| 62216 | 80 | 140 | 33 | 1.51 |

| 62217 | 85 | 150 | 36 | 1.6 |

| 62218 | 90 | 160 | 40 | 1.7 |

| 62219 | 95 | 170 | 43 | 1.8 |

| 62220 | 100 | 180 | 46 | 2.0 |

| 6200 | 10 | 30 | 9 | 0.032 |

| 6201 | 12 | 32 | 10 | 0.036 |

| 6202 | 15 | 35 | 11 | 0.044 |

| 6203 | 17 | 40 | 12 | 0.065 |

| 6204 | 20 | 47 | 14 | 0.11 |

| 6205 | 25 | 52 | 15 | 0.13 |

| 6206 | 30 | 62 | 16 | 0.21 |

| 6207 | 35 | 72 | 17 | 0.288 |

| 6208 | 40 | 80 | 18 | 0.368 |

| 6209 | 45 | 85 | 19 | 0.416 |

| 6210 | 50 | 90 | 20 | 0.463 |

| 6211 | 55 | 100 | 21 | 0.603 |

| 6212 | 60 | 110 | 22 | 0.789 |

| 6213 | 65 | 120 | 23 | 0.99 |

| 6214 | 70 | 125 | 24 | 1.084 |

| 6215 | 75 | 130 | 25 | 1.171 |

| 6216 | 80 | 140 | 26 | 1.448 |

| 6217 | 85 | 150 | 28 | 1.803 |

| 6218 | 90 | 160 | 30 | 2.71 |

| 6219 | 95 | 170 | 32 | 2.62 |

| 6220 | 100 | 180 | 34 | 3.19 |

| 6221 | 105 | 190 | 36 | 3.78 |

| 6222 | 110 | 200 | 38 | 4.42 |

| 6224 | 120 | 215 | 40 | 5.3 |

| 6226 | 130 | 230 | 40 | 6.12 |

| 6228 | 140 | 250 | 42 | 7.77 |

| 6230 | 150 | 270 | 45 | 9.78 |

| 6232 | 160 | 290 | 48 | 12.22 |

| 6234 | 170 | 310 | 52 | 15.241 |

| 6236 | 180 | 320 | 52 | 15.581 |

| 6238 | 190 | 340 | 55 | 18.691 |

| 6240 | 200 | 360 | 58 | 22.577 |

| 62312 | 60 | 130 | 46 | 2.422 |

| 62313 | 65 | 140 | 48 | 3 |

| 62314 | 70 | 150 | 51 | 3.55 |

| 62315 | 75 | 160 | 55 | 4 |

| 62316 | 80 | 170 | 58 | 4.5 |

| 62317 | 85 | 180 | 60 | 5.1 |

| 62318 | 90 | 190 | 64 | 6.1 |

| 62319 | 95 | 200 | 67 | 6.9 |

| 6300 | 10 | 35 | 11 | 0.053 |

| 6301 | 12 | 37 | 12 | 0.06 |

| 6302 | 15 | 42 | 13 | 0.082 |

| 6303 | 17 | 47 | 14 | 0.115 |

| 6304 | 20 | 52 | 15 | 0.142 |

| 6305 | 25 | 62 | 17 | 0.232 |

| 6306 | 30 | 72 | 19 | 0.346 |

| 6307 | 35 | 80 | 21 | 0.457 |

| 6308 | 40 | 90 | 23 | 0.639 |

| 6309 | 45 | 100 | 25 | 0.837 |

| 6310 | 50 | 110 | 27 | 1.082 |

| 6311 | 55 | 120 | 29 | 1.367 |

| 6312 | 60 | 130 | 31 | 1.71 |

| 6313 | 65 | 40 | 33 | 2.1 |

| 6314 | 70 | 150 | 35 | 2.55 |

| 6315 | 75 | 160 | 37 | 3.05 |

| 6316 | 80 | 170 | 39 | 3.61 |

| 6317 | 85 | 180 | 41 | 4.284 |

| 6318 | 90 | 190 | 43 | 4.97 |

| 6319 | 95 | 200 | 45 | 5.74 |

| 6320 | 100 | 215 | 47 | 7.09 |

| 6321 | 105 | 225 | 49 | 8.05 |

| 6322 | 105 | 240 | 50 | 9.53 |

| 6324 | 120 | 260 | 55 | 12.2 |

| 6326 | 130 | 280 | 58 | 14.77 |

| 6328 | 140 | 300 | 62 | 18.33 |

| 6330 | 150 | 320 | 65 | 21.87 |

| 62300 | 10 | 35 | 17 | 0.073 |

| 62301 | 12 | 37 | 17 | 0.571 |

| 62302 | 15 | 42 | 17 | 0.105 |

| 62303 | 17 | 47 | 19 | 0.146 |

| 62304 | 20 | 52 | 21 | 0.195 |

| 62305 | 25 | 62 | 24 | 0.306 |

| 62306 | 30 | 72 | 27 | 0.478 |

| 62307 | 35 | 80 | 31 | 0.647 |

| 62308 | 40 | 90 | 33 | 0.885 |

| 62309 | 45 | 100 | 36 | 1.156 |

| 62310 | 50 | 110 | 40 | 1.498 |

| 62311 | 55 | 120 | 43 | 1.918 |

| 6403 | 17 | 62 | 17 | 0.27 |

| 6404 | 20 | 72 | 19 | 0.4 |

| 6405 | 25 | 80 | 21 | 0.53 |

| 6406 | 30 | 90 | 23 | 0.735 |

| 6407 | 35 | 100 | 25 | 0.952 |

| 6408 | 40 | 110 | 27 | 1.221 |

| 6409 | 45 | 120 | 29 | 1.52 |

| 6410 | 50 | 130 | 31 | 1.855 |

| 6411 | 55 | 140 | 33 | 2.316 |

| 6412 | 60 | 150 | 35 | 2.811 |

| 6413 | 65 | 160 | 37 | 3.342 |

| 6414 | 70 | 180 | 42 | 4.896 |

| 6415 | 75 | 190 | 45 | 5.739 |

| 6416 | 80 | 200 | 48 | 6.752 |

| 6417 | 85 | 210 | 52 | 7.933 |

| 6418 | 90 | 225 | 54 | 9.56 |

| 623 | 3 | 10 | 4 | 0.002 |

| 624 | 4 | 13 | 5 | 0.003 |

| 625 | 5 | 16 | 5 | 0.005 |

| 626 | 6 | 19 | 6 | 0.008 |

| 627 | 7 | 22 | 7 | 0.014 |

| 628 | 8 | 24 | 8 | 0.016 |

| 629 | 9 | 26 | 8 | 0.019 |

| 62200 | 10 | 30 | 14 | 0.044 |

| 62201 | 12 | 32 | 14 | 0.053 |

| 62202 | 15 | 35 | 14 | 0.065 |

| 62203 | 17 | 40 | 16 | 0.096 |

| 62204 | 20 | 47 | 18 | 0.15 |

| 62205 | 25 | 52 | 18 | 0.178 |

| 62206 | 30 | 62 | 20 | 0.215 |

| 62207 | 35 | 72 | 23 | 0.31 |

| 62208 | 40 | 80 | 23 | 0.406 |

| 62209 | 45 | 85 | 23 | 0.455 |

| 62210 | 50 | 90 | 23 | 0.496 |

| 62211 | 55 | 100 | 25 | 0.81 |

| 62212 | 60 | 110 | 28 | 1.03 |

| 62213 | 65 | 120 | 31 | 1.25 |

| 62214 | 70 | 125 | 31 | 1.3 |

| 62215 | 75 | 130 | 31 | 1.4 |

Application

1. Automatic controlling machine

2. Semi-conductor industry

3. General industry machinery

4. Medical equipment

5. Solar energy equipment

6. Machine tool

7. Parking system

8. High-speed rail and aviation transportation equipment, etc.

FAQ

1. who are we?

We are a professional company providing custom design solution to global customers. After decades of development.

There’re over 120 bearing models, more than 4000 part numbers and more than 200 machined partsin our product range. Ball Bearings produced by us are widely used in household appliances, financial equipment, textile industry,motor, office equipment, measuring tools, automobile bearings and other fields.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what can you buy from us?

Deep Groove Ball Bearing,Flange Bearing,Single Row Angular Contact Bearing,Double Row Angular Contact Ball Bearing.

4. why should you buy from us not from other suppliers?

With decades’ experience in producing electrical and electronic products,in addition to the production of bearings,To ensure that our products are of high quality, affordable and provide buyers with the best service.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Double |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Material: | Bearing Steel |

| Spherical: | Aligning Bearings |

| Load Direction: | Radial Bearing |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the primary functions of radial bearings in machinery and equipment?

Radial bearings play several primary functions in machinery and equipment. They are essential components that provide support, facilitate smooth rotation, and minimize friction in various mechanical systems. Here is a detailed explanation of the primary functions of radial bearings:

1. Load Support:

The primary function of radial bearings is to support loads in machinery and equipment. Radial bearings are designed to withstand radial loads, which are forces that act perpendicular to the shaft’s axis. These loads can include the weight of rotating shafts, belts, pulleys, or other components that exert a radial force. Radial bearings distribute the load evenly across the rolling elements and transmit it to the stationary outer ring. By supporting and distributing the load, radial bearings prevent excessive stress on the rotating components and ensure smooth operation.

2. Facilitating Smooth Rotation:

Radial bearings are crucial for facilitating smooth rotation in machinery and equipment. The rolling elements, such as balls or rollers, in a radial bearing roll between the inner and outer rings. This rolling action reduces friction and enables smooth motion of the rotating shaft or assembly. The low friction provided by radial bearings minimizes energy loss and allows machinery to operate efficiently. By enabling smooth rotation, radial bearings contribute to the overall performance and functionality of the machinery or equipment.

3. Reducing Friction and Power Loss:

Friction is an inherent challenge in mechanical systems that can lead to power loss, heat generation, and premature wear. Radial bearings are designed to minimize friction between the rolling elements and raceways. The rolling motion of the elements reduces sliding friction, resulting in lower power loss and improved energy efficiency. By reducing friction, radial bearings help optimize the performance of machinery and equipment, allowing them to operate with increased reliability and efficiency.

4. Absorbing and Damping Vibrations:

Machinery and equipment can experience vibrations due to various factors, such as imbalances, misalignments, or external forces. Radial bearings play a role in absorbing and damping vibrations within the system. The rolling elements and the bearing structure act as a buffer, absorbing and dissipating vibrations generated during operation. By absorbing vibrations, radial bearings reduce the impact on other components, minimize the risk of damage or excessive wear, and contribute to a smoother and quieter operation of the machinery.

5. Supporting Axial Loads (Limited):

Although radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as thrust or pushing forces. While radial bearings are not specifically optimized for axial loads like dedicated thrust bearings, they can handle moderate axial loads that may be present in certain applications. However, it is important to consider the axial load capacity of the specific radial bearing and ensure that the applied axial load remains within its limits.

6. Enabling Compact and Space-Efficient Designs:

Radial bearings offer the advantage of enabling compact and space-efficient designs in machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions and tighter tolerances. By using radial bearings, machinery and equipment can be more compact, lightweight, and efficient without compromising their performance or load-carrying capabilities. This space-saving feature is particularly valuable in applications where space constraints or weight considerations are critical factors.

7. Providing Mechanical Stability:

Radial bearings contribute to the mechanical stability of machinery and equipment. They help maintain the proper alignment of rotating components, preventing excessive vibration, misalignment, or skewing. The precise fit and alignment of the bearing components ensure that the rotating shaft or assembly operates within the desired tolerances. This mechanical stability provided by radial bearings is crucial for the overall performance, reliability, and longevity of the machinery or equipment.

In summary, the primary functions of radial bearings in machinery and equipment include load support, facilitating smooth rotation, reducing friction and power loss, absorbing and damping vibrations, supporting limited axial loads, enabling compact designs, and providing mechanical stability. Radial bearings play a critical role in optimizing the performance, reliability, and efficiency of various mechanical systems.

How do radial bearings perform in high-speed or high-load applications?

Radial bearings are designed to perform reliably in high-speed or high-load applications, where they are subjected to demanding operating conditions. These bearings are engineered to withstand the forces and speeds associated with such applications. Here’s a detailed explanation of how radial bearings perform in high-speed or high-load applications:

1. High-Speed Applications:

In high-speed applications, radial bearings are designed to minimize friction and reduce heat generation. They employ various features to achieve this, such as optimized ball or roller designs, precise manufacturing tolerances, and advanced cage materials. These design elements help reduce centrifugal forces, improve rolling element guidance, and maintain stable operation at high rotational speeds. Additionally, high-quality lubricants are used to ensure proper lubrication and temperature control, enabling the bearing to operate efficiently and reliably even at high speeds.

2. High-Load Applications:

Radial bearings are engineered to handle high loads encountered in various applications. They are designed with robust construction, using high-quality materials and advanced bearing geometries. These features enable radial bearings to distribute the applied loads evenly across their contact surfaces, minimizing stress concentrations and preventing premature failure. Additionally, radial bearings may incorporate specialized cage designs or additional rollers or balls to enhance their load-carrying capacity. The selection of the appropriate bearing type and size, along with proper lubrication, is crucial to ensure optimal performance and longevity in high-load applications.

3. Heat Dissipation:

In both high-speed and high-load applications, radial bearings must effectively dissipate heat generated during operation. Excessive heat can lead to premature bearing failure or degradation of lubricants. Radial bearings are designed with features that promote efficient heat dissipation, such as internal clearances, optimized bearing materials, and effective lubrication systems. These features help maintain the operating temperature within acceptable limits, ensuring the integrity and performance of the bearing in demanding conditions.

4. Cage Design:

The cage design of radial bearings is an essential factor in their performance in high-speed or high-load applications. The cage holds the rolling elements in position, preventing contact and ensuring proper spacing. In high-speed applications, cages with low friction and good guidance properties are used to minimize heat generation and maintain stable operation. In high-load applications, stronger and stiffer cage materials are employed to withstand the forces exerted by the applied loads. The cage design is optimized to balance the trade-off between strength, guidance, and friction characteristics, ensuring the reliable performance of the radial bearing under demanding conditions.

5. Lubrication and Contamination Control:

In high-speed or high-load applications, proper lubrication is crucial for the performance and longevity of radial bearings. Lubricants with high viscosity and excellent thermal stability are used to ensure adequate lubrication under extreme conditions. Effective lubrication minimizes friction, reduces wear, and controls temperature rise. Additionally, contamination control is essential to prevent abrasive particles or contaminants from entering the bearing and causing damage. Sealing solutions and proper maintenance practices are employed to safeguard the bearing against contamination in high-speed or high-load applications.

6. Application-Specific Considerations:

When using radial bearings in high-speed or high-load applications, it is important to consider the specific requirements and conditions of the application. Factors such as operating temperature, rotational speed, applied loads, vibration levels, and environmental conditions should be taken into account during the bearing selection process. Working closely with bearing manufacturers or industry experts can help ensure that the chosen radial bearings are suitable for the specific high-speed or high-load application, optimizing performance and maximizing bearing life.

In summary, radial bearings are designed to perform reliably in high-speed or high-load applications. Through their specialized design, robust construction, efficient heat dissipation, optimized cage designs, proper lubrication, and consideration of application-specific factors, radial bearings can meet the challenges of demanding operating conditions, providing reliable and long-lasting performance.

Can you describe the various types of seals and shields used with radial bearings for contamination prevention?

Seals and shields are commonly used with radial bearings to prevent contamination and protect the bearing internals from external particles, moisture, and other contaminants. They help maintain the integrity of the lubricant and extend the service life of the bearing. Here’s a detailed description of the various types of seals and shields used with radial bearings:

1. Contact Seals:

Contact seals, also known as lip seals or radial lip seals, are designed to make direct contact with the inner ring of the bearing. They consist of a flexible sealing lip that forms a barrier between the inner and outer ring of the bearing. Contact seals effectively prevent the entry of contaminants into the bearing by creating a tight seal. They are commonly made of rubber or elastomeric materials and provide effective sealing against solid particles, liquids, and gases. Contact seals offer good contamination prevention but may generate higher friction and heat compared to non-contact seals.

2. Non-Contact Seals:

Non-contact seals, also known as labyrinth seals or gap seals, do not make direct contact with the inner ring of the bearing. Instead, they rely on a series of barriers or labyrinth-like structures to create a tortuous path that prevents the entry of contaminants. Non-contact seals provide effective protection against solid particles, such as dust and dirt, while allowing for minimal friction and heat generation. They are commonly made of metal or plastic and are suitable for high-speed applications where reduced friction is critical.

3. Shielded Bearings:

Shielded bearings, also known as metal shields or ZZ bearings, are equipped with metallic shields that cover the outer surface of the bearing. These shields are usually made of steel and provide a physical barrier against contaminants. Shielded bearings are designed to prevent the entry of larger particles, such as dirt and debris, while allowing for the circulation of lubricating grease within the bearing. However, they do not provide a complete seal and may not be suitable for applications where protection against moisture or fine particles is required.

4. Rubber Seals:

Rubber seals, also known as rubber contact seals or RS bearings, are similar to contact seals but are made entirely of rubber or elastomeric materials. They provide effective sealing against contaminants, including solid particles, liquids, and gases. Rubber seals offer good contamination prevention and are more flexible than other sealing options, allowing for better adaptability to varying operating conditions. They are commonly used in applications where protection against moisture, dust, and other fine particles is essential.

5. Felt Seals:

Felt seals are made of compressed or woven felt material and are used primarily in low-speed applications. They provide a barrier against larger particles and help retain lubricating oil or grease within the bearing. Felt seals are relatively simple and cost-effective solutions for contamination prevention. However, they may not offer the same level of protection as other sealing options and may require regular lubrication to maintain their effectiveness.

6. Combination Seals:

Combination seals utilize a combination of different sealing mechanisms to provide enhanced contamination prevention. These seals often incorporate both contact and non-contact elements to create an effective barrier against various contaminants. Combination seals are designed to address specific application requirements, providing a balance between sealing effectiveness, friction, heat generation, and other performance factors.

7. Additional Features:

Some seals and shields may incorporate additional features to enhance contamination prevention. For example, seals may include dust lips or auxiliary lips to provide extra protection against fine particles. Shields may have gap fillers or flingers to deflect contaminants away from the bearing. These additional features help improve the sealing effectiveness and contribute to extended bearing life.

When selecting seals and shields for radial bearings, it is essential to consider the specific application requirements, operating conditions, and the level of contamination protection needed. Manufacturers typically provide guidelines and recommendations regarding the appropriate sealing options for their bearings to ensure optimal performance and reliability.

editor by CX 2024-03-27