Product Description

1,Durable and high Quality.

2,Nice-looking packing.

3,Prompt delivery.

4,Wide range of parts for more models available.

5,OEM production welcome

6,Most competitive wholesale prices.

7. One stop buying service provided.

More parts available,please contact us

Our company is located in HangZhou and specialized in manufacturing and trading of moto parts and accessories.We could supply the parts for the popular Japanese brand,Chinese brands and Indian brand motorcycles.

With an experienced and professional team, we have exported our products to many countries and regions all over the world, especially Latin America,Middle East,East Europe and Africa.Our products enjoy a good reputation among our customers. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We could supply parts for more models including Honda,Suzuki,Yamaha,Bajaj,TVS.and Chinese motos Qingqi,Keeway,Benelli,Haojue,Sanyua,Xihu (West Lake) Dis.n etc. For more parts and catalog,Welcome to contact us. Website:

| The hot selling parts: | |

| Scooter parts | Gy6 50/125/150 scooter parts,AN125,WH125 scooter parts,Keeway scooter parts |

| 2-stroke parts | JOG50 3KJ,AG100,Dio50,MBK,PGT BUXY,PIAGIO TYPHOON,AX100 |

| Bajaj parts | BM150,BM100,Dscover135,Pulsar200,200NS,XCD,3W4S,Platino etc |

| Tricycle parts | 200cc cargo tricycle,250cc/300cc tricycles,and bajaj 3w4s parts,TVS king |

| Engine parts | Cylinder,piston,head,gear sets,camshaft,gear sets,camshaft,plug,bearings etc |

| Electrical parts | CDI,regulator,stator coil,start motor,start relay |

| Brake parts | Brake pad,brake shoes,brake caliper,disc,brake pumps |

| Body parts | Kick lever,gear levers,footstep,shock absorbers,meters, fuel tank,seat |

| Transmission | Drive chain,sprockets,cam chain,chain lock,wheel hub,and covers |

| Switches | Ignition switches,lock sets,fuel cap,hand switches,fuel cock |

| The models we work for: | |

| HONDA | CG150/200/250,CGL125,XL125,GL125 KYY,CBF125 KTT,CB110,CBR190,CB125, XR150,CRF230,NXR125,WAVE110,WH125,CBX125,BIZ110,XL200,JH70 ETC |

| YAMAHA | CRYPTON T105 T110,YBR125,YB125,YS150 FAZER,FZ16,XTZ125,XT225,DT175 JOG50 3KJ,JOG 3YK,JOG 3KJ ,JOG 4JP,CY80,DX100,BWS125,RX115 ETC |

| SUZUKI | AX4 GD110,AX100,GN125H,EN125,AN125,GS125,GIXXER150,YES125,GN125 INTRUDER,SMASH110,FT110 ETC |

| OTHER MOTOS | SYM,TVS,ITALIKA,GENESIS,EUROMOT,UM,AKT,YUMBO,MOTOMEL,ZENELLA, MONDIAL,LIFAN,ZONGSHEN,LONCIN,XIHU (WEST LAKE) DIS.,XIHU (WEST LAKE) DIS.N,HangZhou,ZONTES ETC |

The hot parts available:

FAQ:

1. Why choose us?

We are professional in the moto parts business in China mianland. We are confident that with our experience,quality,service can give our customers complete satisfaction.

2. MOQ:

It is between 100 or 200pcs or sets,it depends on the parts. For some parts,200pcs is a start,for some big parts,for 50pcs,there is no problem.

3.Mode of Delilivery

it could be by air,by sea (LCL,FCL) or by express (DHL/UPS/TNT/FEDEX).

we can delivery it according to your option.

4. Delivery time:

We could make delivery within 15 or 20 days after your deposit payment. Also it depends on what kind of parts you buy. For some parts,if we have stock,it will be very quick,one week will be ok.

5. Payment:

we accept T/T payment,L/C and Western union. Actually,we use T/T more,namely by 30% deposit,balance could be paid before or after loading.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

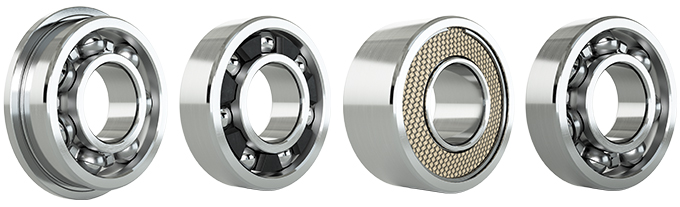

| Rolling Body: | Ball Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Medium and Large(120-190mm) |

| Material: | Stainless Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Radial Bearing |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the primary functions of radial bearings in machinery and equipment?

Radial bearings play several primary functions in machinery and equipment. They are essential components that provide support, facilitate smooth rotation, and minimize friction in various mechanical systems. Here is a detailed explanation of the primary functions of radial bearings:

1. Load Support:

The primary function of radial bearings is to support loads in machinery and equipment. Radial bearings are designed to withstand radial loads, which are forces that act perpendicular to the shaft’s axis. These loads can include the weight of rotating shafts, belts, pulleys, or other components that exert a radial force. Radial bearings distribute the load evenly across the rolling elements and transmit it to the stationary outer ring. By supporting and distributing the load, radial bearings prevent excessive stress on the rotating components and ensure smooth operation.

2. Facilitating Smooth Rotation:

Radial bearings are crucial for facilitating smooth rotation in machinery and equipment. The rolling elements, such as balls or rollers, in a radial bearing roll between the inner and outer rings. This rolling action reduces friction and enables smooth motion of the rotating shaft or assembly. The low friction provided by radial bearings minimizes energy loss and allows machinery to operate efficiently. By enabling smooth rotation, radial bearings contribute to the overall performance and functionality of the machinery or equipment.

3. Reducing Friction and Power Loss:

Friction is an inherent challenge in mechanical systems that can lead to power loss, heat generation, and premature wear. Radial bearings are designed to minimize friction between the rolling elements and raceways. The rolling motion of the elements reduces sliding friction, resulting in lower power loss and improved energy efficiency. By reducing friction, radial bearings help optimize the performance of machinery and equipment, allowing them to operate with increased reliability and efficiency.

4. Absorbing and Damping Vibrations:

Machinery and equipment can experience vibrations due to various factors, such as imbalances, misalignments, or external forces. Radial bearings play a role in absorbing and damping vibrations within the system. The rolling elements and the bearing structure act as a buffer, absorbing and dissipating vibrations generated during operation. By absorbing vibrations, radial bearings reduce the impact on other components, minimize the risk of damage or excessive wear, and contribute to a smoother and quieter operation of the machinery.

5. Supporting Axial Loads (Limited):

Although radial bearings are primarily designed to support radial loads, they can also withstand limited axial (thrust) loads. Axial loads are forces that act parallel to the shaft’s axis, such as thrust or pushing forces. While radial bearings are not specifically optimized for axial loads like dedicated thrust bearings, they can handle moderate axial loads that may be present in certain applications. However, it is important to consider the axial load capacity of the specific radial bearing and ensure that the applied axial load remains within its limits.

6. Enabling Compact and Space-Efficient Designs:

Radial bearings offer the advantage of enabling compact and space-efficient designs in machinery and equipment. Their ability to support loads and facilitate smooth rotation allows engineers to design systems with smaller dimensions and tighter tolerances. By using radial bearings, machinery and equipment can be more compact, lightweight, and efficient without compromising their performance or load-carrying capabilities. This space-saving feature is particularly valuable in applications where space constraints or weight considerations are critical factors.

7. Providing Mechanical Stability:

Radial bearings contribute to the mechanical stability of machinery and equipment. They help maintain the proper alignment of rotating components, preventing excessive vibration, misalignment, or skewing. The precise fit and alignment of the bearing components ensure that the rotating shaft or assembly operates within the desired tolerances. This mechanical stability provided by radial bearings is crucial for the overall performance, reliability, and longevity of the machinery or equipment.

In summary, the primary functions of radial bearings in machinery and equipment include load support, facilitating smooth rotation, reducing friction and power loss, absorbing and damping vibrations, supporting limited axial loads, enabling compact designs, and providing mechanical stability. Radial bearings play a critical role in optimizing the performance, reliability, and efficiency of various mechanical systems.

Can radial bearings be customized or modified for unique industrial needs?

Radial bearings can indeed be customized or modified to meet unique industrial needs. Manufacturers often offer customization options to provide bearings that are tailored to specific application requirements. Customization allows for the optimization of various aspects of the bearing, such as size, design, materials, lubrication, and sealing, among others. Here’s a detailed explanation of the customization and modification possibilities for radial bearings:

1. Size and Design:

Radial bearings can be customized in terms of size and design to fit specific space constraints or load requirements. Manufacturers can adjust the dimensions of the bearing, such as the bore diameter, outer diameter, or width, to match the application’s unique specifications. Additionally, the bearing design can be modified to accommodate specific performance needs, such as increased load capacity, enhanced stiffness, or improved rotational speed capabilities.

2. Materials:

The choice of materials used in radial bearings can be customized based on the application’s needs. Different materials offer varying levels of strength, corrosion resistance, temperature resistance, and other properties. For example, in high-temperature environments, bearings can be customized with heat-resistant materials, such as ceramic or high-temperature alloys, to ensure reliable operation. Similarly, for applications where corrosion is a concern, bearings can be customized with corrosion-resistant coatings or materials.

3. Lubrication:

Radial bearings can be customized in terms of lubrication requirements. The lubrication type and quantity can be modified to suit specific operating conditions. For instance, bearings operating in high-speed applications may require specialized lubricants that can withstand high temperatures and provide sufficient lubrication film thickness. Customized lubrication solutions can help optimize bearing performance, reduce friction, and extend the bearing’s service life.

4. Sealing and Protection:

Bearing customization can include modifications to the sealing and protection features. Seals or shields can be customized to provide enhanced protection against contaminants, moisture, or other environmental factors. By choosing the appropriate sealing solution, the ingress of dust, dirt, or liquids can be minimized, improving the bearing’s reliability and longevity. Customized sealing options can also help reduce maintenance requirements and prevent premature failure.

5. Specialized Coatings:

In certain industrial applications, specialized coatings can be applied to radial bearings to enhance their performance. These coatings can provide benefits such as increased wear resistance, reduced friction, improved corrosion resistance, or enhanced operating characteristics under specific conditions. Customized coatings can be designed based on the specific application needs, ensuring optimal performance and longevity of the bearings in demanding environments.

6. Mounting and Fit:

Customization of radial bearings can include modifications to the mounting and fit requirements. For unique applications where standard mounting methods are not suitable, manufacturers can customize the bearing’s mounting features to ensure proper fit and alignment within the system. This may involve modifications to the bearing’s outer ring, inner ring, or flange design to accommodate specific mounting arrangements or requirements.

7. Application-Specific Considerations:

Manufacturers of radial bearings are often willing to work closely with customers to understand their unique industrial needs and develop customized solutions. By considering application-specific factors such as load conditions, operating environment, speed requirements, and space limitations, manufacturers can tailor the design and specifications of radial bearings to provide optimal performance and reliability.

It is important to note that customization of radial bearings may involve additional costs and lead time compared to off-the-shelf bearings. However, the benefits of having bearings specifically tailored to the application’s requirements often outweigh these considerations, as they can result in improved performance, increased service life, and reduced downtime.

Overall, radial bearings can be customized or modified to meet unique industrial needs, allowing for the optimization of various parameters to ensure optimal performance, reliability, and longevity in specific applications. Collaborating with bearing manufacturers or industry experts can help identify the customization possibilities and develop tailored solutions that address the specific requirements of the industrial application.

What are the eco-friendly or sustainable aspects of radial bearing materials?

Radial bearing materials play a crucial role in determining the environmental impact and sustainability of the bearings. Several aspects of radial bearing materials contribute to their eco-friendliness and sustainability. Here’s a detailed explanation of these aspects:

1. Material Selection:

The choice of bearing material can have a significant impact on its environmental footprint. Opting for materials that are eco-friendly and sustainable is important. Some materials commonly used in radial bearings, such as steel, have high recycling rates and can be recycled at the end of their life cycle. This reduces the demand for new raw materials and minimizes waste generation. Additionally, selecting materials that are abundant and easily sourced further enhances the sustainability of radial bearings.

2. Recyclability:

Radial bearings made from recyclable materials are considered environmentally friendly. When bearings reach the end of their useful life, they can be recycled, and the materials can be repurposed for manufacturing new bearings or other products. Recycling reduces the need for virgin materials extraction, conserves resources, and reduces energy consumption and greenhouse gas emissions associated with the production of new materials. Choosing bearing materials that are easily recyclable promotes a circular economy and minimizes waste generation.

3. Reduced Environmental Impact:

Some radial bearing materials have a lower environmental impact compared to others. For example, selecting materials with lower carbon footprints or materials that require less energy-intensive manufacturing processes can contribute to sustainability. Materials like ceramic or composite bearings often have lower energy requirements during production compared to traditional steel bearings. By reducing energy consumption and associated emissions, these materials help mitigate the environmental impact of bearing manufacturing.

4. Lubrication and Friction Reduction:

The choice of bearing material can also influence the lubrication requirements and friction levels. Bearings made from materials with inherent self-lubricating properties or low friction coefficients can reduce the need for external lubrication or the use of lubricants with potential environmental impacts. Self-lubricating materials such as polymers or certain composites can minimize the use of oil or grease lubricants, which can be environmentally harmful if not managed properly. Reduced lubrication requirements contribute to sustainable bearing operation by minimizing lubricant consumption and potential contamination risks.

5. Extended Service Life:

Using durable and long-lasting bearing materials helps extend the service life of the bearings. Bearings that require less frequent replacement or maintenance have a positive impact on sustainability. By reducing the frequency of bearing replacements, less waste is generated, and the consumption of raw materials is minimized. Additionally, extending the service life of bearings reduces the need for energy-intensive manufacturing processes associated with frequent replacements, further reducing the environmental impact.

6. Energy Efficiency:

Radial bearing materials can contribute to energy efficiency in mechanical systems. Materials with low friction coefficients and high wear resistance properties help minimize energy losses due to friction and improve overall system efficiency. By reducing energy consumption, sustainable bearing materials support energy conservation efforts and contribute to the reduction of greenhouse gas emissions associated with energy production.

7. Compliance with Environmental Regulations:

Eco-friendly and sustainable radial bearing materials often comply with environmental regulations and standards. These materials are designed to meet specific requirements regarding the use of hazardous substances, waste generation, and disposal. Compliance with regulations such as the Restriction of Hazardous Substances (RoHS) directive ensures that bearing materials are free from harmful substances, protecting human health and the environment.

8. Life Cycle Assessment:

A comprehensive life cycle assessment (LCA) of bearing materials can provide insights into their environmental impact. LCA evaluates the environmental effects associated with a product throughout its entire life cycle, from raw material extraction to end-of-life disposal. Conducting LCAs helps identify areas of improvement, optimize manufacturing processes, and select materials with lower environmental impacts.

By considering these eco-friendly and sustainable aspects of radial bearing materials, manufacturers and end-users can make informed choices that minimize their environmental footprint. Sustainable bearing materials contribute to resource conservation, waste reduction, energy efficiency, and compliance with environmental regulations, fostering a more sustainable and environmentally responsible industrial ecosystem.

editor by CX 2024-03-29