Product Description

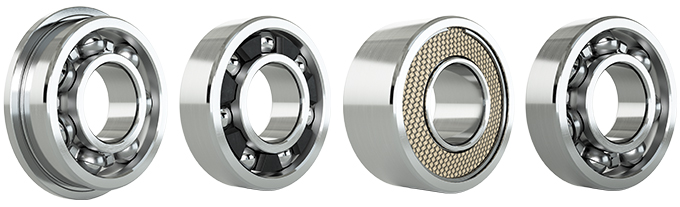

High Quality Tc Radial Bearings for 228mm Series Trenchless Directional Downhole Motor

Product Description

HangZhou Shengde TC bearings, high strength, long life inlaid carbide radial bearings is our company’s proprietary technology, is currently the earliest domestic production of radial bearings company. Radial bearings inside and outside the surface of the regular arrangement of cemented carbide blocks and special composition of solder, cemented carbide filler, through the special sintering treatment, so that it and the base parts fused into one. Its friction vice has the outstanding features of corrosion resistance, impact resistance, large load bearing and long service life, and its appearance quality and technical indexes have exceeded those of similar foreign products.

Detailed Photos

Product Parameters

| Type | 228 | |

| Material | 40CrMnMo YG8 | |

| The size of alloys | 25*10*2.5 | |

| length (mm) | customized | |

| Connection | customized | |

| Features | high strength, long life | |

| All sizes can be customized | ||

Certifications

Company Profile

HangZhou Shengde Petroleum Machinery Manufacturing Co. , Ltd. is a professional company integrating R & D, design and production. China National Petroleum Corporation (CNPC) and China National Petroleum Sinopec Corporation (CNPC) are first-class network suppliers of oil drilling and production machinery manufacturing. The main products are Downhole Motor series, screw pump series, PDC bit series. Compared with the domestic and foreign product quality, in the leading level. The annual production capacity has reached 4000 sets of screw drilling tools and 800 sets of screw pump series. The products are sold to domestic and foreign markets and are widely praised and praised by customers.

Our Advantages

1.We have more than 20 years of TC radial bearing production experience, is the China National Petroleum Corporation (CNPC) , Sinopec company (CNPC) oil drilling and production machinery manufacturing network supplier.

2.We have an independent physical and chemical laboratory, professional inspection engineers, can handle any mechanical performance tests and heat treatment experiments

3.All kinds of TC radial bearing models complete, dedicated to serve you

FAQ

Q: How much the transportation freight ?

A:The freight depends on the weight and packing size and destination from here to your location

Q: How to control quality?

A:1. all the raw materials by IQC (Incoming Quality Control )before launch whole process into the process after the screening.

2. process each link in the process of IPQC (Input process quality control)patrol inspection.

3. after finished by QC full inspection before packing into the next process packaging.

4. OQC before shipment for each downhole motor to do full inspection.

Q: Are you manufactory or trade company?

A:We are the Manufactory specialized in Petroleum equipment industry products for many years already. Our factory have passed IS09001:2014, API. And we are AAA grade credit enterprise.

Also we had large warehouse and quality control department for purchasing products for clients.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Available |

|---|---|

| Warranty: | 1year |

| Manufacturing Process: | CNC Milling |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do radial bearings contribute to reduced friction and smooth rotation in machinery?

Radial bearings play a crucial role in reducing friction and promoting smooth rotation in machinery. Their design and construction contribute to minimizing contact between moving parts, optimizing efficiency, and enhancing overall performance. Here is a detailed explanation of how radial bearings achieve reduced friction and smooth rotation:

1. Rolling Elements:

Radial bearings typically incorporate rolling elements, such as balls or rollers, between the inner and outer races. These rolling elements reduce friction compared to sliding contact between surfaces. As the bearing rotates, the rolling elements roll instead of slide, resulting in lower frictional forces and reduced energy loss. The rolling action of the elements contributes to smoother rotation and improved efficiency.

2. Lubrication:

Lubrication is essential for reducing friction and ensuring smooth rotation in radial bearings. Lubricants, such as oils or greases, are used to create a thin film between the rolling elements and raceways. This lubricating film separates the surfaces, minimizing direct contact and friction. The lubricant also helps to dissipate heat generated during operation, preventing excessive temperature rise and potential damage to the bearing. Proper lubrication is critical to maintaining low friction and promoting smooth rotation in radial bearings.

3. Bearing Clearance and Preload:

The clearance or preload adjustment in radial bearings also contributes to reduced friction and smooth rotation. Bearing clearance refers to the intentional space left between the rolling elements and raceways, allowing for thermal expansion and accommodating operating conditions. Adequate clearance ensures that the bearing components can move freely without excessive interference, minimizing friction. On the other hand, preload is a controlled axial force applied to eliminate clearance and maintain a slight internal load on the bearing. Preload helps to reduce internal clearances, improve stiffness, and minimize any potential play or vibration, resulting in smoother rotation.

4. Bearing Material and Surface Finish:

The choice of bearing material and surface finish significantly impacts friction and smooth rotation. Radial bearings are commonly made from materials such as steel, ceramic, or polymer composites. These materials offer excellent hardness, wear resistance, and low friction characteristics. Additionally, the surfaces of the bearing components undergo precise machining and finishing processes to achieve smoothness and minimize surface irregularities. The combination of suitable materials and high-quality surface finishes promotes reduced friction and smooth rotation in radial bearings.

5. Bearing Design and Internal Geometry:

The design and internal geometry of radial bearings are optimized to minimize friction and promote smooth rotation. Factors such as the number and size of rolling elements, the contact angle, and the curvature of the raceways are carefully engineered to ensure proper load distribution and minimize stress concentrations. Well-designed bearing cages also help maintain the correct spacing and alignment of the rolling elements, reducing friction and ensuring smooth rotation. The overall design and geometry of radial bearings are crucial for achieving optimal performance and minimizing frictional losses.

6. Precision Manufacturing:

Radial bearings are manufactured with high precision to achieve tight tolerances and minimize variations in dimensions. Precision manufacturing processes, such as grinding and superfinishing, ensure that the bearing components have accurate shapes and smooth surfaces. This precision manufacturing contributes to reduced friction and smooth rotation by minimizing irregularities and imperfections that can cause excess friction or vibration.

In summary, radial bearings contribute to reduced friction and smooth rotation in machinery through the use of rolling elements, proper lubrication, optimized bearing clearance or preload, suitable materials and surface finishes, well-engineered designs, and precision manufacturing. These factors work together to minimize contact, reduce frictional forces, and ensure efficient and reliable operation of machinery and equipment.

What is the impact of proper lubrication on the performance and lifespan of radial bearings?

Proper lubrication plays a crucial role in the performance and lifespan of radial bearings. It is essential to provide adequate lubrication to minimize friction, reduce wear, and ensure reliable operation. Here’s a detailed explanation of the impact of proper lubrication on the performance and lifespan of radial bearings:

1. Friction Reduction:

Proper lubrication forms a thin film of lubricant between the rolling elements and raceways of the bearing. This lubricating film reduces friction and minimizes the resistance to rotation, allowing the bearing to operate smoothly. Reduced friction results in lower energy consumption, decreased heat generation, and improved overall efficiency of the bearing system.

2. Wear Prevention:

Effective lubrication helps prevent wear and damage to the bearing surfaces. The lubricant forms a protective layer that separates the rolling elements from the raceways, preventing direct metal-to-metal contact. This separation minimizes wear, surface fatigue, and the risk of premature bearing failure. Proper lubrication significantly extends the lifespan of radial bearings by preserving their working surfaces.

3. Temperature Control:

Lubrication plays a critical role in controlling the operating temperature of radial bearings. The lubricant absorbs and dissipates heat generated during operation, preventing excessive temperature rise. Adequate lubrication helps maintain the bearing within the optimal temperature range, reducing the risk of thermal damage and preserving the integrity of the bearing components.

4. Contamination Protection:

Proper lubrication forms a barrier against contaminants such as dirt, dust, moisture, and particles. The lubricant acts as a protective shield, preventing these contaminants from entering the bearing and causing damage. Effective lubrication helps maintain the cleanliness of the bearing, reducing the risk of abrasive wear, corrosion, and other forms of contamination-induced failure.

5. Corrosion Prevention:

Lubrication helps prevent corrosion and rust formation on the bearing surfaces. The lubricant forms a protective film that acts as a barrier, preventing moisture and corrosive agents from reaching the metal surfaces. By inhibiting corrosion, proper lubrication enhances the longevity and reliability of radial bearings, particularly in demanding environments or applications exposed to moisture and corrosive substances.

6. Noise and Vibration Reduction:

Effective lubrication contributes to reducing noise and vibration levels in radial bearings. The lubricant absorbs and dampens the vibrations generated during operation, resulting in smoother and quieter bearing performance. Proper lubrication helps minimize noise pollution, enhances user comfort, and improves the overall operation of machinery and equipment.

7. Load Capacity Enhancement:

Appropriate lubrication can enhance the load-carrying capacity of radial bearings. The lubricant’s lubricating properties and film thickness help distribute the applied loads evenly across the bearing surfaces, reducing stress concentrations. This allows the bearing to support higher loads and handle heavier operating conditions without compromising its performance or lifespan.

8. Reliability and Longevity:

Overall, proper lubrication significantly enhances the reliability and longevity of radial bearings. It minimizes wear, reduces friction, prevents damage, controls temperature, protects against contamination, inhibits corrosion, reduces noise and vibration, and improves load-carrying capacity. By ensuring optimal lubrication conditions, the performance and lifespan of radial bearings are maximized, leading to improved equipment uptime, reduced maintenance requirements, and increased operational efficiency.

In conclusion, proper lubrication is essential for achieving optimal performance, longevity, and reliability of radial bearings. It minimizes friction, reduces wear, controls temperature, protects against contamination and corrosion, and enhances load-carrying capacity. Regular monitoring and maintenance of lubrication conditions are crucial to ensure the continued smooth operation and extended lifespan of radial bearings.

How do radial bearings enhance the overall efficiency and functionality of machinery and equipment?

Radial bearings play a critical role in enhancing the overall efficiency and functionality of machinery and equipment. They enable smooth and reliable rotational motion, reduce friction, support heavy loads, and provide stability. Here’s a detailed explanation of how radial bearings contribute to the efficiency and functionality of machinery and equipment:

1. Reduced Friction:

Radial bearings are designed to minimize friction between moving parts. By providing a smooth interface between rotating components, they reduce energy losses due to friction. This results in improved energy efficiency and reduced power consumption. Bearings with low friction characteristics help optimize the performance of machinery by minimizing heat generation, reducing wear, and preventing premature failure of components.

2. Load Support:

Radial bearings are specifically designed to support radial loads, which are forces acting perpendicular to the rotation axis. They distribute the applied loads evenly across the bearing surfaces, preventing excessive stress on individual components. By efficiently supporting loads, radial bearings help maintain the structural integrity of machinery and equipment, ensuring smooth operation and preventing component failures.

3. Shaft Alignment and Stability:

Radial bearings contribute to the alignment and stability of rotating shafts. They help maintain accurate positioning of the shafts, ensuring proper alignment with other components. This alignment minimizes vibrations, reduces noise, and avoids unnecessary wear and tear. By providing stability, radial bearings enable machinery to operate smoothly and with precision, enhancing overall functionality.

4. Increased Rotational Speed:

Radial bearings are designed to accommodate high rotational speeds. They provide smooth rolling or sliding motion, minimizing the centrifugal forces generated at high speeds. By allowing machinery and equipment to operate at higher speeds, radial bearings enhance productivity and throughput. Increased rotational speed can lead to shorter processing times, higher production rates, and improved overall efficiency.

5. Noise and Vibration Reduction:

Properly selected and maintained radial bearings help reduce noise and vibration in machinery and equipment. They act as dampers, absorbing and dissipating vibrations generated by rotating components. By minimizing vibrations, radial bearings contribute to a quieter operating environment, improve operator comfort, and reduce the risk of damage to sensitive components.

6. Compact Design and Space Optimization:

Radial bearings are available in various sizes and configurations, allowing for compact design and space optimization in machinery and equipment. Their small footprint and high load-carrying capacity make them ideal for applications with limited space. By enabling compact designs, radial bearings facilitate the integration of additional components, reduce the overall size of the equipment, and increase efficiency in terms of space utilization.

7. Maintenance and Reliability:

Radial bearings require regular maintenance to ensure optimal performance and reliability. However, compared to other components in machinery and equipment, bearings are relatively easy to maintain. Proper lubrication, monitoring of operating conditions, and periodic inspection can help prevent premature failure and extend the service life of bearings. By reducing downtime and the need for frequent repairs, radial bearings enhance the overall efficiency and functionality of machinery.

8. Application Versatility:

Radial bearings are available in a wide range of types, sizes, and materials, making them versatile for various applications. Different bearing configurations and materials can be selected based on specific operational requirements, load conditions, and environmental factors. This versatility allows engineers to optimize the performance and efficiency of machinery and equipment for specific applications, ensuring reliable operation and maximizing productivity.

Overall, radial bearings are essential components that significantly enhance the efficiency and functionality of machinery and equipment. By reducing friction, supporting loads, providing stability, accommodating high speeds, minimizing noise and vibration, enabling compact designs, facilitating maintenance, and offering application versatility, radial bearings contribute to the smooth operation, improved performance, and extended service life of machinery and equipment in various industries.

editor by CX 2024-03-27